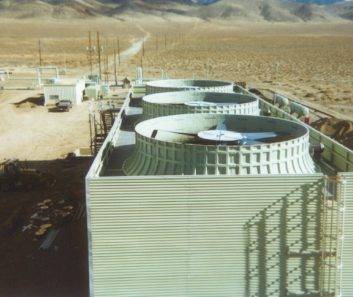

Project: Vinachem Project

Industry: Chemical – Fertilizer Production

Location: Tang Loong Industrial Zone – Boa Thank District, Lao Cai Province, Vietnam

Tower Type: 4-Cell, Concrete

Client: Toyo Thai (TTCL)

Year: 2011

Project: Vinachem Project

Industry: Chemical – Fertilizer Production

Location: Tang Loong Industrial Zone – Boa Thank District, Lao Cai Province, Vietnam

Tower Type: 4-Cell, Concrete

Client: Toyo Thai (TTCL)

Year: 2011

Reasons for A Cooling Tower Replacement

Like any other large piece of industrial equipment, the ravages of time eventually take their toll on a cooling tower’s capacity. At a certain point, routine maintenance and patchwork replacement of components is no longer enough to ensure that a cooling tower is capable of achieving the performance necessary to support its intended application.

In order to extend the life of a cooling tower and boost its cooling capacity, a reconstruction project may become necessary; this will ensure that your business is able to continue to function properly for the foreseeable future.

Benefits of Cooling Tower Replacement

In addition to enhancing a cooling tower’s intended capacity, reconstruction also presents the opportunity to upgrade a tower’s structural components. Cooling tower fill &motor replacement can easily be completed during these projects if the tower’s fill is clogged or damaged, allowing for higher-performing pieces to be implemented.

How to Proceed Once Your Cooling Tower Has Been Completed

Once your reconstruction project is done, it’s important that you discuss recommendations on a maintenance schedule and scope with your supplier in order to avoid any degradation of your updated cooling tower. A qualified manufacturer should be able to provide you with concrete advice specific to your situation, and may even be able to offer assistance with the servicing itself.

As a general rule, every cell of your tower should receive an inspection every year of components like gearboxes (plus gearbox oil and seals), driveshafts, distribution water basins, fan cylinders, fill, and distribution piping and nozzles among others.

Why Us?

Industrial Cooling Solutions is a global team of industry experts; we offer construction and service all over the world backed by years of knowledge and experience.

Project: Palinpinon Geothermal Power Plant

Industry: Geothermal

Location: Philippines

Client: EDC

Tower Type: Crossflow, FRP

Year: 2012-13

ICS was contracted for demolition and cooling tower replacement of Unit #1 of Palinpinon Geothermal Power Plant owned by EDC Philippines. The project was set on a very tight schedule to demolish a dilapidated old 3-cell class 600 Marley wood tower and replace it with a new ICS FRP crossflow cooling tower in 42 days from start to finish. ICS was able to complete this complex job two days early

Project: Empire Energy/Empire Farms Garlic Farm

Industry: Geothermal

Location: Nevada

Tower Type: 3-Cell, Counterflow, FRP

Project: Shintech Tower Replacement

Industry: Chemical

Location: Freeport, TX

Tower: 3-Cell, Wood Crossflow to Counterflow Fiberglass FRP Conversion

Year: 2015

Counterflow to Crossflow Conversion: Working closely with the owner, ICS demolished an existing and failing Marley 3-cell, wood, crossflow cooling tower and installed a new ICS FRP counter-flow cooling tower with higher capacity in the existing basin. The new tower was up and operating within 22 days to fit within a critical plant outage. ICS closely coordinated with the customer to make certain all project concerns were addressed professionally and to the customer’s satisfaction before mobilization. then perfectly executed upon mobilization. Safety was a major concern of the customer and ICS met and exceeded all expectations with a zero incident completion. ICS is committed to safety in all aspects of our business.

ICS provides our customers with high performance cooling towers designed to meet or exceed project requirements. This crossflow to counterflow conversion required perfect execution in a tight schedule. ICS worked with the engineering team, maintenance and operations team closely to ensure we understood and worked well with the plant rules and requirements yet still completed a complex schedule on time. Ask ICS how we can help you complete your most complex projects safely, on time and on budget.

ICS has completed many crossflow to counterflow conversions with splash to film fill conversions and performance upgrades. Call or email to learn more. ICS works within the existing basin and maximizes performance by optimizing design and materials selections to ensure the right cooling tower for the project and at the right price. Ask how ICS can improve your plant performance by providing more cold water in the same existing basin giving you a quick return on investment (ROI). Marley, GEA, PSI, Hamon, Fluor or other brands, ICS has the expertise to upgrade your cooling tower to gain maximum performance and minimize total cooling tower power savings.

Contact Us

Project: Cawayan Crossflow to Counterflow Conversion Project

Industry: Geothermal Power

Location: Philippines

Tower: 2-Cell, Fiberglass FRP Splash Fill to Film Fill Conversion

Year: 2011

FRP Geothermal Cooling Tower Counterflow to Crossflow Conversion:

ICS was contracted by EDC to build a new FRP film fill counterflow cooling tower in the existing basin where a GEA wood crossflow had burned down. ICS was able to complete the project quickly and provide EDC with a fire retardant cooling tower which would not burn down like the wooden cooling tower. ICS’s FRP cooling tower also did not require a wetdown system or a fire protection system as 100% of the FRP and plastic materials supplied were rated at a 25 or less flame spread rating. Working in the jungle rain and heat, ICS was able to complete the tower in the existing basin on schedule and was commended by the owner for being the first to complete works on the site.

Geothermal cooling towers are specialized applications. ICS has global experience and expertise in geothermal cooling tower applications. Working with FRP, wood, concrete and concrete/FRP structures, ICS can custom design to your project specification. Low-fouling Film or splash fill, ICS works with you to determine the best fill selection for your project. ICS also consults with our cooling water treatment alliance partners to make certain the choice is right for the project.

Contact Us

ICS performed complete “splash fill” to “film fill” conversions and total tower rehabilitation (structure, mechanical, decking) under a tight time schedule and with a perfect safety record for two counterflow, wood, six-cell towers.

Project: BacMan 3

Industry: Geothermal

Location: Philippines

Tower Type: 6-Cell, Counterflow, Wood

Client: EDC

Year: 2011

Cooling Tower Rehabilitation with Splash to Film Fill Conversion:

ICS was hired to help EDC Philippines with a major upgrade of an old geothermal power station. Two 6-cell Hamon wooden structure splash fill cooling towers were in bad shape and in need of serious repair. EDC also wanted to maximize backpressure on the turbine. ICS offered and guaranteed substantial cooling tower performance upgrades which would help. ICS was selected to do an extensive rehabilitation and thermal upgrade of the towers on a very tight budget. ICS replaced more than 70% of the structure & mechanical equipment but reused what was possible to save cost. Splash fill was removed and a low-fouling film fill was installed. The reduced pumphead from the splash to film conversion saves EDC power consumption everyday. The added performance allowed EDC to greatly improve plant performance. ICS completed our works on schedule and was the first contractor to complete works in this very remote and difficult site.

Ask ICS how we can support your cooling tower rehabilitation projects splash to film fill conversions, structural upgrades, mechanical upgrades and overall thermal upgrades to your project.

Project: Thailand Projects

Industries: Oil & Gas, Petrochemical, Power – Thermal

Location: Thailand

Clients: PTT General Chemical Group, IRPC, PTT Gas, Siam Cement Group (SCG), Thai Plastics, Thai Olefins (TOC), Laemchabang Power, Navanakorn Power, GulfJP, TTCL, Toyo Japan, Samsung, SKEC, Foster Wheeler and others

Year: 2012 through Current

Thailand Cooling Tower Professionals: ICS is the “go to” professional cooling tower brand name in Thailand. When you need the right answer from professionally trained cooling tower and air cooler specialists, ICS is your resource. in addition to supplying and servicing ICS’s new counterflow and crossflow towers, ICS Thailand (ICST) services our customers for all brands of cooling towers (SPX – Marley, GEA, Hamon and others) with the Thailand’s best service technicians, spare parts and pricing. if your current supplier is failing you, call ICS/ICST to learn how we can solve your most complex issues professionally and quickly and at a fair price. ICS and ICST are your Thailand Cooling Tower Professionals.

ICS and ICST have been chosen for many prestigious projects in Thailand. Projects include GulfJP’s 12SPP project of 12 new gas fired cogeneraiton power plants in Thailand. IRPC’s UHV project, PTT’s largest cracking project and the downstream LLDPE, LDPE and BPA projects. ICS is proud to have earned the trust of professional clients in Thailand and globally for these cogeneration and petrochemical projects. ICST Thailand also regularly performs general inspections and maintenance work on cooling towers and air coolers for our Thai clients. Anything from tower cleaning & gearbox rebuilding services to complete fill replacements and thermal upgrades. Learn more about ICS’s Thailand Projects by contacting us at our Thai or USA offices.

ICS’s Thailand projects include many projects for PTT Group, IRPC, GulfJP, Thai Plastics, Thai Olefins, Laemchabang Power, Navanakorn Power, TTCL, Toyo Japan, Foster Wheeler, SKEC, Samsung and others. ICS and ICS Thailand (ICST) work with owners for Operations & Maintenance (O&M) as well as upgrades, thermal upgrades and spare parts supply in Thailand and throughout the region. Working closely with our ICS Thailand office, ICS offers our customers complete turnkey services for all industrial type cooling towers and air coolers. USA, Thailand and Japan based engineering resources assure our clients of the international design and engineering standards. Our Thai and Philippines teams support the construction and after sales services they need to complete new, repair/upgrade and general maintenance projects. Call ICS or ICS Thailand for the best service, pricing and performance in Thailand.

Contact Us

Project: KBR

Industry: Manufacturing

Location: United States

Tower: 6-Cell, Crossflow, FRP

Year: 2015

Project: Palinpinon 3

Industry: Geothermal

Location: Philippines

Client: EDC

Year: 2012-2013

Contact Us

Project: Palinpinon 2

Industry: Geothermal

Location: Philippines

Tower Type: Crossflow, FRP

Client: EDC

Year: 2012-2013