Fin fans or air-cooled heat exchangers are widely utilized in oil, gas, refining, chemical, power, and other heavy industries. It’s necessary to keep your ACHE performing well because it’s a crucial part of your production process.

Through a wide range of consultancy, maintenance, and cleaning services, ICS provides cooling capacity to improve and optimize the operation of your ACHE.

Need even more performance? Ask ICS about fan upgrades which can increase your ACC & ACHE performance by up to 40%.

There are various ways to increase the performance of your current ACHE without buying new air coolers. We provide a modern, green solution to guarantee your air cooler systems’ best performance and lifespan.

Cleaning the tube bundle is one of the best ways to increase ACHE duty. The fin-tube rows may be clogged with organic and inorganic material that cannot be seen from the top or bottom of the units, Your air coolers will be immaculate when our qualified crew successfully removes impurities, dirt, and deposits from cooling bundles using the power of dry soda blasting.

Other Cleaning Options

Systems such as high-pressure washing tend to clog or damage tube fins, while acidic foam cleaners can be corrosive to the steel structures, and both of these cleaning methods require shutting down the system to clean.

Hydro Blasting can deeply clog tube bundles and damage fins. Why clog when you can safely, effectively clean with ICS low-pressure Soda Blasting?

Dry soda blasting successfully removes impurities and debris from fin tube bundles while maintaining the structural integrity of the cooling bundles.

The fin tube bundle is thoroughly visually inspected by our competent experts beforehand. This evaluation aids in our comprehension of the level of contamination, the nature of the fouling, and any possible problems that may arise.

Our innovative dry soda blasting gear is ready for the cleaning procedure. This contains the blasting machine, a regulated compressed air supply, and the proper grade of Dry Soda Blast appropriate for the material and state of the fin tube bundle.

Our professionals carefully monitor the cleaning process during the blasting operations. To ensure complete cleaning while preserving the integrity of the fin tube bundle, adjustments are made to pressure and distance as needed.

After the dry soda blasting, the fin tube bundle is thoroughly inspected. This examination confirms that all impurities and debris have been successfully eliminated. No special cleanup is required as the baking soda disperses as it cleans.

Throughout the procedure, thorough records are kept, including pictures taken before and after cleaning, pressure settings, and observations.

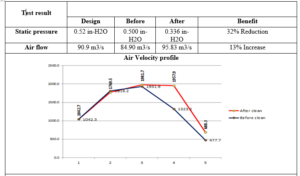

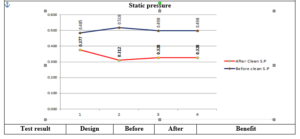

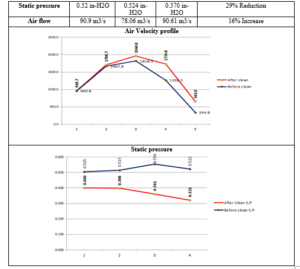

ICS Soda Blasting = Proven Results

Say goodbye to outdated, chemical-filled cleaning techniques. Accept the power of our ground-breaking Soda cleaning method. Why it’s the finest option for your air coolers is as follows:

ICS Teams make use of specialized cleaning equipment. ICS Dry Cleaning gives you performance at the top of the industry by utilizing the most specialized equipment and skilled staff.

To break up and remove the fouling without harming the fins or tubes, the ICS Dry Cleaning process uses industrial-grade “coarse grain” soda blasted via a specific pressurized system. Our cleaning solution is Not-toxic and water-soluble & safe for workers. It will not damage or puncture fins or tubes, it is GREEN & SAFE.

ICS Dry Cleaning is non-corrosive, environmentally friendly, and leaves no chemical residue as it is blasted into the system dry and thus is harmlessly dispersed by the ACHE.

ICS Dry Cleaning is performed while your unit is running, thus eliminating shutdowns & no special preparation of the unit is required. ICS Dry Cooling does not require entry into the unit or access to the top of the unit, and we clean from the ground level, thus reducing safety permitting and concerns.

ICS Dry Cleaning provides immediate performance results as the fouling is removed from the system. Your control room will see increased performance in the system as we clean. ICS Group would be pleased to work with you to optimize your Air Coolers further to maximize the cooling and performance of the plant with ICS’s GUARANTEED upgrades.

We are committed to providing unparalleled service that goes beyond simple cleaning. Our goal is to completely transform how industrial air coolers are maintained so they operate at their peak efficiency and protect the environment for the coming generations

To arrange your service, contact the helpful staff at ICS now!

Contact ICS USA, Japan or Thailand today for your free consultation