A cooling tower is a heat removal plant designed to lower industrial water temperature by transferring excess heat into the atmosphere. It works by circulating water through the system and using either evaporation or air cooling to reduce heat efficiently. Industrial cooling towers rely on evaporating a small amount of water to cool the rest, while dry cooling towers use air to achieve the same result without water loss.

A cooling tower operates by transferring heat from hot water to the atmosphere, effectively lowering its temperature. Water from the hot water basin is evenly distributed through cooling tower spray nozzles that create a fine mist. As the water interacts with moist outside air, latent heat is removed through evaporation. This process cools the water to a temperature near the wet bulb temperature. The cooled water collects in the cold water basin for reuse in the cooling system. High-efficiency towers, often paired with a chiller and cooling tower, effectively manage heat load, aided by high exiting air velocities and saturated discharge air for optimum performance.

ICS is a preferred cooling tower provider specializing in cooling tower engineering & construction, thermal upgrades and replacement cooling towers worldwide.

Our cooling tower construction services provide our clients with highly reliable, turnkey solutions, including new cooling tower engineering and structures as well as cooling tower repair and parts–all designed to best meet each client's needs.

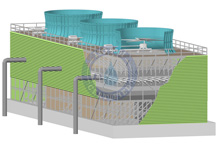

ICS also offers complete water cooling tower systems, including civil design, civil works and piling, pumps, piping, cable trays, and other auxiliary equipment.

When working with owners on an existing project or expansion, ICS is your one-stop supplier for all cooling tower systems and will act as the General Contractor to provide turnkey design, engineering, procurement, supply, and installation for the entire water cooling tower block.

Have a low-performing tower? ICS also provides cooling tower repairs, reconstruction, thermal upgrades, and cooling tower parts for industrial cooling towers of all makes and models.

ICS counterflow and crossflow cooling towers are widely utilized by thermal power plants, as well as Utility, IPP, SPP, and Private operators. These cooling towers support a range of fuels, from traditional coal to cleaner alternatives like gas, geothermal, and biomass. Special designs are available to meet specific needs, including splash fill, film fill, low foul fill, low noise application, and a variety of other customized designs.

The expert team of ICS specializes in designing, constructing, and repairing geothermal cooling towers. We also integrate special considerations into the design to offer operational efficiency and durability for harsh environments.

ICS provides customized forced draft cooling towers designed for demanding applications like acid plants. These specialty towers are engineered in industrial facilities to withstand extreme corrosion and fouling conditions. With robust construction and advanced materials, we ensure reliable operation and minimize downtime. ICS towers support various fertilizer production processes, enhancing overall efficiency and productivity.

Being a versatile service provider, ICS delivers tailored cooling solutions for diverse applications, from refining and cracking to intermediate processing. In addition, we offer water treatment chemicals that improve the effectiveness and longevity of cooling units. We assist petrochemical and chemical facilities in maintaining high production and efficiency while minimizing interruptions, resulting in a safe and cost-effective operation.

ICS creates customized cooling solutions to ensure continuous operation and maximum efficiency. This enables metal and mining operations to run smoothly and productively. Our tailored approach meets the unique needs of this demanding industry.

Our expert solutions are for various HVAC systems and general industrial processes. We design and supply high-performance cooling towers that ensure reliable operation and optimal efficiency. From manufacturing to energy production, our systems support critical processes.

A petrochemical process converts saturated hydrocarbons into smaller, often unsaturated ones. ICS provides cooling solutions that support this critical process, ensuring efficient and reliable operation. Our expertise helps cracking complexes run smoothly and safely.

In the oil and gas refining industry, cooling systems play a crucial role. ICS provides upgrades or new cooling towers that efficiently cool the hot water essential to refining operations. Our solutions help refineries maintain optimal performance, reduce downtime, and ensure continuous production.

ICS Counterflow towers are available in induced draft, forced draft, concrete, FRP, and wood structures, as well as splash fill, film fill, and low fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allow ICS to maintain the highest standards yet meet competitive demands.

ICS Crossflow towers are available in the induced draft, forced draft, concrete, FRP, and wood structures, as well as splash fill, film fill, and low-fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allow ICS to maintain the highest standards yet meet competitive demands.

Forced and induced draft cooling towers differ primarily in the placement of their fans and airflow direction. Forced draft towers have fans at the base, pushing air through the system, making them suitable for customers who have highly corrosive environments in which it is best to keep the mechanical equipment out of the airstream.

Induced draft towers, on the other hand, have fans at the top, pulling air upward against the downward flow of water, which is ideal for most heavy industrial cooling applications due to their efficient heat transfer and compact design. Cooling tower used in heavy industrial cooling systems.

Natural draft cooling towers draw air through convection, whereas mechanical draft towers move air with fans. Natural towers are energy efficient since they do not require mechanical fans for heat transfer, making them ecologically friendly and cost-effective to operate.

Cooling towers were built with wood, which was abundant and resistant to decay. However, modern wood towers raise environmental concerns and face fluctuating costs due to varying availability. Although wood is treated for durability, it remains vulnerable to rot and fire risks. Today, alternative materials, such as plastic ( delta cooling towers) and stainless steel, offer:

FRP is reliable, durable, and cost-efficient with many advantages:

Tangential Benefits

Depending on the country, location within the country, and availability of other materials, concrete may or may not be cost-effective when measured against importing other media. Concrete may have higher initial costs but continues to be a good choice for projects in many countries and has these benefits:

Together with our cooling tower water treatment partners, ICS provides total care solutions for our customers, including system audits and Operations & Maintenance solutions to help you maintain your tower efficiency at its highest level. Chemical water treatment solutions can be packaged with new ICS Counterflow and Crossflow cooling towers and ICS repair and upgrade solutions for existing cooling towers.

Do you have an old Marley or small cooling tower that is not performing? Call ICS to see how we can bring total solutions and help you achieve maximum cooling tower efficiency with any water condition.

Cooling tower water filtration is often required to ensure manageable water conditions with modern film, low-clog, and low-fouling film fill materials. Side stream filtration complements proper fill selection and water treatment to help cooling towers maintain optimal performance and minimize maintenance requirements.

Have any questions regarding cooling tower engineering & construction? Contact Us

ICS is a preferred cooling tower provider specializing in cooling tower engineering & construction, thermal upgrades and replacement cooling towers worldwide.

Our cooling tower construction services provide our clients with highly reliable, turnkey solutions including new cooling tower engineering and structures as well as cooling tower repair and component parts–all designed to best meet each clients needs.

ICS also offers complete water cooling tower systems including civil design, civil works and piling, pumps, piping, cable trays and other auxiliary equipment.

When working with owners on an existing project or expansion, ICS is your one-stop supplier for all cooling tower systems and will act as the General Contractor to provide

turnkey design, engineering, procurement, supply and installation for the entire water cooling tower block.

Complete Cooling Tower Services:

ICS provides the industrial industry with Counterflow and Crossflow cooling towers constructed of wood, fiberglass (FRP) or concrete, customized for your cooling needs with film fill, splash fill or hybrid fill.

Have a low-performing tower? ICS also provides cooling tower repairs, reconstruction, thermal upgrades and cooling tower parts for existing industrial cooling towers of all makes and models.

Towers By Industry

POWER GENERATION: ICS counterflow and crossflow cooling towers are utilized by Utility, IPP, SPP and Private operators. Fuels range from coal to gas, geothermal and biomass.

Special designs include splash fill, film fill, low foul fill, low noise application and a variety of other designs.

GEOTHERMAL: ICS specializes in the design, construction, and repair of geothermal cooling towers and integrates special considerations into the design in order to offer operational efficiency and durability for harsh environments.

FERTILIZER: ICS supplies forced draft specialty towers for Acid plants and all ranges of high corrosion and fouling situations.

PETROCHEMICAL/CHEMICAL: From refining to cracking and everything in between, ICS has the petrochemical design and experience you can count on.

METALS/MINING: Specialty designs for metals and mining to ensure high availability of operation and optimal performance.

PROCESS: ICS services all heavy industrial, HVAC and general process industries where performance and high reliability cooling towers are required.

CRACKING COMPLEXES: Steam cracking is a petrochemical process in which saturated hydrocarbons are broken down into smaller, often unsaturated, hydrocarbons.

REFINING: Upgrades or new towers for oil-and-gas refining to cool the water integral to the operations.

COUNTERFLOW:

ICS Counterflow towers are available in induced draft, forced draft, concrete, FRP and wood structure as well as splash fill, film fill and low fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allows ICS to maintain the highest standards yet meet competitive demands.

CROSSFLOW:

ICS Crossflow towers are available in induced draft, forced draft, concrete, FRP and wood structure as well as splash fill, film fill and low fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allows ICS to maintain the highest standards yet meet competitive demands.

INDUCED DRAFT: Standard Induced Draft towers suitable for most heavy industrial cooling applications.

FORCED DRAFT: Forced Draft towers are designed for customers who have highly corrosive environments in which it is best to keep the mechanical equipment out of the airstream.

The majority of components on early cooling towers, including the structure, were made of naturally decay resistant wood. Today, wood towers are subject to environmental concerns and cost fluctuations based on availability. Wood is treated to improve longevity but is susceptible to decay and fire hazards.

FRP is reliable, durable, and cost efficient with many advantages:

Tangential Benefits

Depending on the country, location within the country and availability of other materials, concrete may or may not be cost effective when measured against importing other media. Concrete may have higher initial costs but continues to be a good choice for projects in many countries and has these benefits:

Together with our cooling tower water treatment partners, ICS provides total care solutions for our customers which includes system audits and Operations & Maintenance solutions to help you maintain your tower efficiency at its highest level. Chemical water treatment solutions can be packaged with new ICS Counterflow and Crossflow cooling towers as well as ICS repair and upgrade solutions of existing cooling towers.

Do you have an old Marley or Hamon cooling tower which is not performing? Call ICS to see how we can bring total solutions to you and help you achieve maximum cooling tower efficiency with any water condition.

Cooling tower water filtration is often required to ensure manageable water conditions with modern film, low-clog and low-fouling film fill materials. side stream filtration is a good compliment to proper fill selection and water treatment to help cooling towers maintain optimal performance and minimize maintenance requirements.

Have any questions regarding cooling tower engineering & construction? Contact Us