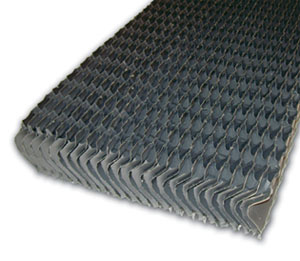

DE120 is designed for applications requiring very low drift levels in counterflow or crossflow cooling towers, evaporative cooling systems, and scrubbers.

Product Weights & Span Capabilities

| Blade Thickness |

Dry Weight |

Maximum Span |

| lbs/ft2 |

kg/m2 |

| 25 mils (0.64 mm) |

0.9 |

4.4 |

6 ft (1.8 m) |

Materials

DE120 Blade Drift Eliminators are available in UV-stabilized PVC and HPVC (for high temperatures). These compounds have outstanding resistance to weather exposure and are nearly impervious to chemical degradation by alkalis, acids, greases, fats, oils, and biological attacks. They also have an excellent fire rating due to their self-extinguishing characteristics and meet or exceed Cooling Technology Institute Standard 136.

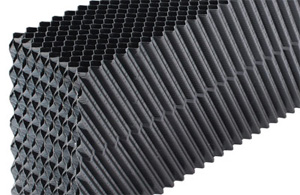

Product description

DE120 Blade Drift Eliminator Modules use a series of sinusoidal-shaped PVC (or HPVC) blades to achieve excellent drift droplet removal by forcing the leaving air to make three distinct changes of direction. The 1.2-inch blade spacing allows for good performance at low pressure drop and cost, making the DE120 our most affordable drift eliminator. The blades are held together with one-piece end caps, forming an assembled module that is lightweight but strong enough to span up to 6 feet between supports while also saving material costs, labor costs, and reducing air blockage.