XF80MAx is designed for applications requiring very low drift levels in crossflow cooling towers, evaporative cooling systems, and scrubbers.

Product Weights & Span Capabilities

Nominal Sheet Thickness

(After Forming) |

Dry Weight |

Maximum Span* |

| lbs/ft2 |

kg/m2 |

| Standard: 13 mils (0.38mm) |

1.1 |

5.4 |

8 ft (2.4 m) |

| Heavy Duty: 20 mils (0.51 mm) |

1.5 |

7.3 |

10 ft (3.0 m) |

| *Tested at a maximum air temperature of 115°F (46°C) installed at a 10° maximum angle. |

Materials

All Brentwood Cellular Drift Eliminators are made from PVC material that meets Cooling Technology Institute Standard 136 and are UV-protected. These PVC compounds have outstanding resistance to weather exposure and are nearly impervious to chemical degradation by alkalis, acids, greases, fats, oils, and biological attacks. PVC has an excellent fire rating due to its self-extinguishing characteristics with a flame-spread rating of 25 per ASTM E84.

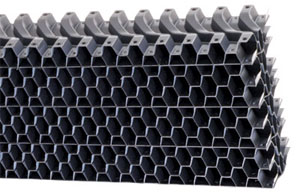

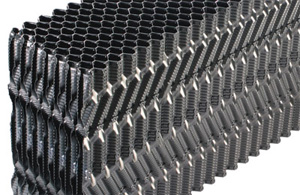

Product description

XF80MAx Crossflow Cellular Drift Eliminators provide the best available drift removal efficiency on the market today. The upward flow path, steep water drainage angle, and tuned venturi section make this the ideal product for factory-built crossflow towers. The modules are constructed of a series of sinusoidal-shaped, corrugated PVC sheets that are mechanically assembled to mating sinusoidal structural waves, forming closed cells. These cells force the drift droplets being carried in the leaving airstream to make three distinct changes in direction. These forced changes to the air flow create centrifugal forces on the droplets that remove them from the air stream by causing them to impact the module walls, collect, and drain back to the wet section of the cooling tower.