ICS is a preferred cooling tower provider specializing in cooling tower engineering & construction, thermal upgrades and replacement cooling towers worldwide.

Our cooling tower construction services provide our clients with highly reliable, turnkey solutions including new cooling tower engineering and structures as well as cooling tower repair and component parts–all designed to best meet each clients needs.

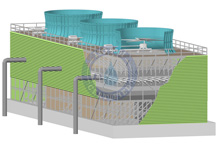

ICS also offers complete water cooling tower systems including civil design, civil works and piling, pumps, piping, cable trays and other auxiliary equipment.

When working with owners on an existing project or expansion, ICS is your one-stop supplier for all cooling tower systems and will act as the General Contractor to provide

turnkey design, engineering, procurement, supply and installation for the entire water cooling tower block.

Complete Cooling Tower Services:

ICS provides the industrial industry with Counterflow and Crossflow cooling towers constructed of wood, fiberglass (FRP) or concrete, customized for your cooling needs with film fill, splash fill or hybrid fill.

Have a low-performing tower? ICS also provides cooling tower repairs, reconstruction, thermal upgrades and cooling tower parts for existing industrial cooling towers of all makes and models.

Towers By Industry

POWER GENERATION: ICS counterflow and crossflow cooling towers are utilized by Utility, IPP, SPP and Private operators. Fuels range from coal to gas, geothermal and biomass.

Special designs include splash fill, film fill, low foul fill, low noise application and a variety of other designs.

GEOTHERMAL: ICS specializes in the design, construction, and repair of geothermal cooling towers and integrates special considerations into the design in order to offer operational efficiency and durability for harsh environments.

FERTILIZER: ICS supplies forced draft specialty towers for Acid plants and all ranges of high corrosion and fouling situations.

PETROCHEMICAL/CHEMICAL: From refining to cracking and everything in between, ICS has the petrochemical design and experience you can count on.

METALS/MINING: Specialty designs for metals and mining to ensure high availability of operation and optimal performance.

PROCESS: ICS services all heavy industrial, HVAC and general process industries where performance and high reliability cooling towers are required.

CRACKING COMPLEXES: Steam cracking is a petrochemical process in which saturated hydrocarbons are broken down into smaller, often unsaturated, hydrocarbons.

REFINING: Upgrades or new towers for oil-and-gas refining to cool the water integral to the operations.

COUNTERFLOW:

ICS Counterflow towers are available in induced draft, forced draft, concrete, FRP and wood structure as well as splash fill, film fill and low fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allows ICS to maintain the highest standards yet meet competitive demands.

CROSSFLOW:

ICS Crossflow towers are available in induced draft, forced draft, concrete, FRP and wood structure as well as splash fill, film fill and low fouling fill materials. ICS cooling towers are designed to meet or exceed the most demanding standards. USA design and global sourcing allows ICS to maintain the highest standards yet meet competitive demands.

INDUCED DRAFT: Standard Induced Draft towers suitable for most heavy industrial cooling applications.

FORCED DRAFT: Forced Draft towers are designed for customers who have highly corrosive environments in which it is best to keep the mechanical equipment out of the airstream.

The majority of components on early cooling towers, including the structure, were made of naturally decay resistant wood. Today, wood towers are subject to environmental concerns and cost fluctuations based on availability. Wood is treated to improve longevity but is susceptible to decay and fire hazards.

FRP is reliable, durable, and cost efficient with many advantages:

Tangential Benefits

Depending on the country, location within the country and availability of other materials, concrete may or may not be cost effective when measured against importing other media. Concrete may have higher initial costs but continues to be a good choice for projects in many countries and has these benefits:

Together with our cooling tower water treatment partners, ICS provides total care solutions for our customers which includes system audits and Operations & Maintenance solutions to help you maintain your tower efficiency at its highest level. Chemical water treatment solutions can be packaged with new ICS Counterflow and Crossflow cooling towers as well as ICS repair and upgrade solutions of existing cooling towers.

Do you have an old Marley or Hamon cooling tower which is not performing? Call ICS to see how we can bring total solutions to you and help you achieve maximum cooling tower efficiency with any water condition.

Cooling tower water filtration is often required to ensure manageable water conditions with modern film, low-clog and low-fouling film fill materials. side stream filtration is a good compliment to proper fill selection and water treatment to help cooling towers maintain optimal performance and minimize maintenance requirements.

Have any questions regarding cooling tower engineering & construction? Contact Us

Copyright© 2024. h2ocooling | All Rights Reserved.