Heat Management in Power Generation

At Industrial Cooling Solutions, all types of cooling are fascinating. Usually, we focus on our special cooling towers, but today, we want to explore another important type of water cooling. This process is crucial for many factories and plants, especially those that generate energy.

When power plants make electricity, they also produce a lot of heat that must be controlled safely, responsibly, and without breaking the bank. That’s where water cooling comes in. Water is used in power plants to absorb and dissipate heat, allowing them to operate more smoothly and effectively. Plants need a specialised system known as the cooling water intake structure to get this cooling water, which takes water from a nearby source, such as a lake or river, to aid in the cooling process.

What is the Importance of Water in Power Plants?

These powerhouses yield electricity for homes, businesses, and industries by converting various forms of energy. These include thermal, nuclear, and renewable energy sources. We get about 90 % of our power supply in the United States from thermoelectric plants. Such manufacturers utilize coal, natural gas, oil, or nuclear rods.

These facilities use their respective energy sources to boil water and generate steam, which is used to spin turbines and produce electricity. Once the steam has travelled through these generators, it must be cooled again before being reintroduced into the power system. Even after a nuclear reactor is turned off, it continues to create decay heat, which must be carefully regulated to avoid scorching.

What are Different Types of Cooling?

To cool the rising steam, thermoelectric plants utilize three main methods. These processes help dissipate heat and maintain efficient operation. When power stations apply these cooling techniques, they can effectively manage steam temperatures and optimize energy production.

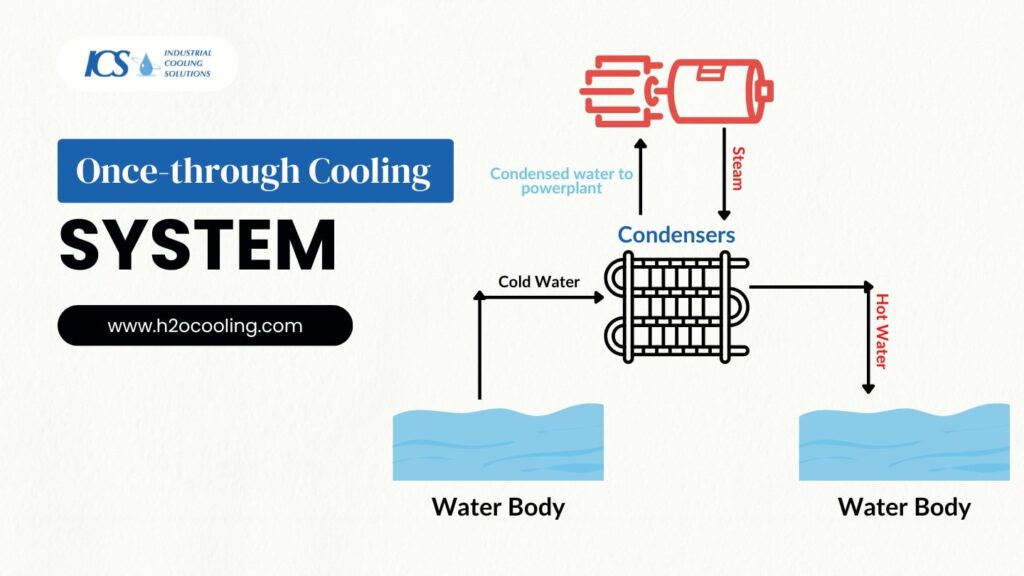

Once-through Cooling System:

In this method of industrial cooling, systems use water from a nearby source, such as lakes, rivers, oceans, etc. The water is then circulated through pipes to absorb the steam’s heat in systems called condensers. Once the water has effectively cooled the steam, it is discharged back into a local water source, where it will naturally cool.

The once-through technique of industrial cooling was initially the most popular form available to plants. The simplicity of the system and the low cost of running it are the main reasons of its usage. While this type of industrial cooling is still widespread in the eastern United States, most new power plants do not use this system to cool steam. This shift away from once-through systems is mainly because these procedures can cause major disruptions to the local ecosystems around the plant. Siphoning water from local water sources and reintroducing warm water into the same system can cause damage to local rivers, lakes, and aquifers.

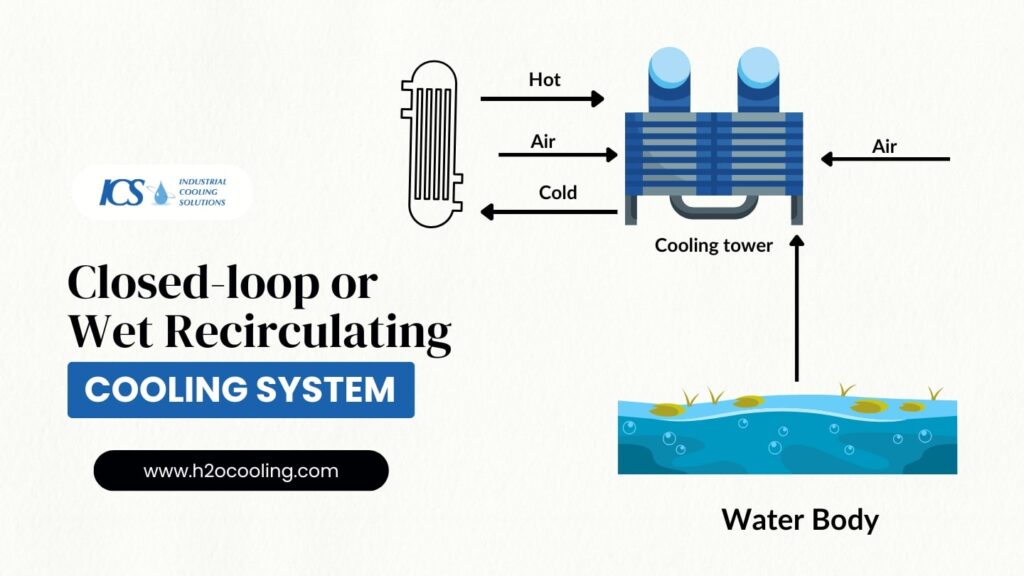

Closed-loop or Wet Recirculating Cooling System:

Closed-loop systems are the main reason that cooling towers even exist. Nuclear plants often utilize a recirculating wet cooling system, which incorporates wet cooling towers. In this method of industrial cooling, heated water is run through a second cycle instead of being discharged back into the original water source. In most recirculating designs, cooling towers are used to lower the temperature of the water by exposing it to the outside ambient air directly.

While some of the water evaporates, the effective use of fill media allows most cooling towers to reclaim the vast majority of water funnelled into them. While these recirculating systems withdraw less water from local sources than once-through systems, they tend to have a considerably higher water consumption rate.

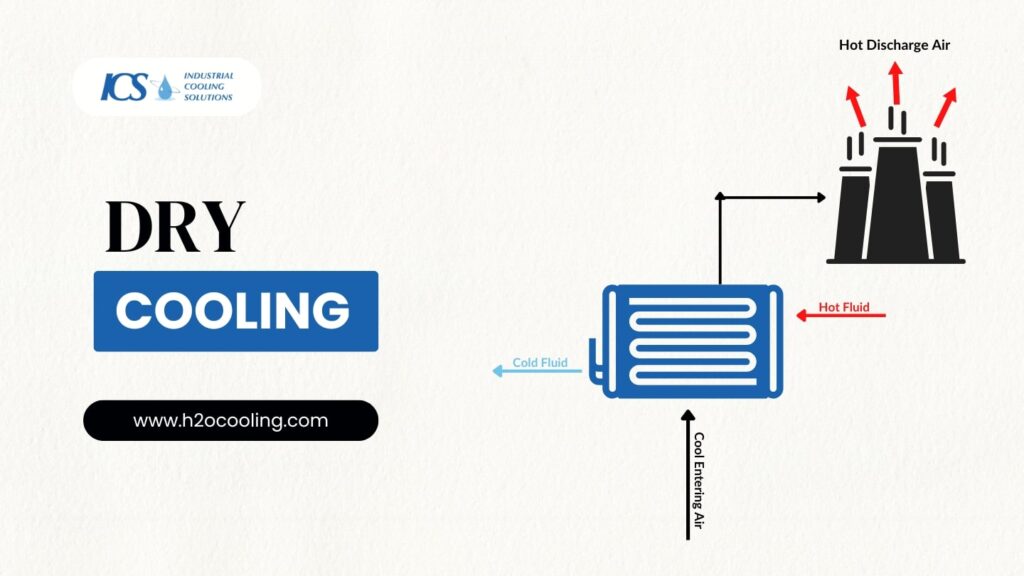

Dry-Cooling:

This type does not rely on water availability; rather, it operates with air to cool the steam as it exits the turbine of a thermoelectric plant. This system does heat transfer by routing the steam towards an array of A-framed tubes while a fan blows the steam directly across the tubes. As the steam passes over the metal tubes, it condenses, and the cooled water is collected for reuse. While dry-cooling systems use no water and can decrease a power plant’s water consumption by up to 90 per cent, they require a higher initial cost and higher auxiliary operating power. They can result in overall lower plant performance and efficiency. Lower plant efficiency means that a plant must use more fuel to produce the same amount of electricity, which can lead to a greater environmental impact. As a result, most dry-cooling systems are only used in small-scale thermoelectric plants.

Advancements in Technology: What’s Coming Next

As technology continues to grow, power plants are also improving in controlling their temperatures. Innovations and a stronger focus on protecting the environment and minimizing thermal pollution are making the future of power plant cooling systems look very bright.

Renewable Energy Sources

By implementing these strategies, nuclear power plants can reduce their environmental impact. These sources include wind and solar systems. Integrating these technologies can reduce their reliance on fossil fuels, lower the emission of greenhouse gases, and enhance the electric generating capacity. They will ultimately contribute to a cleaner and healthier planet.

New Cooling Materials

Scientists are creating new materials that can help power plants cool down more efficiently. Nanoparticles and polymers are the main advancements in this case. These materials can transfer heat more efficiently, require less water, and make the cooling process even more effective.

Smart Cooling

As the name suggests, their systems are equipped with sensors and advanced technology like IoT. These processes help in different ways, like monitoring the cooling process in real-time, making possible and required adjustments, and helping save water. All of these can result in saving energy and boost efficiency.

Wrap up

While we have a preference for closed-loop cooling systems (because they require cooling towers), we can appreciate the other methods of effectively cooling steam as it exits thermoelectric power plants. Industrial Cooling Solutions Inc. has a track record for fast, professional, and safe industrial cooling tower installations, conversions, and upgrades. To learn more about our industrial cooling tower services, visit our website or contact us today. Let us show you the wonders of industrial cooling towers.