Cooling towers are vital parts of many industrial processes because they aid in the dissipation of heat from different systems. They are made up of various components, each of which is essential to the tower’s overall operation.

We’ll examine the many components of a cooling tower and their purposes in this tutorial to give you a thorough grasp of how these systems operate. In this blog we’ll uncover essential cooling tower parts and functions.

Table of Contents (Cooling Tower Parts and Functions)

Fan

A cooling tower’s fan, which is usually found at the top of the structure, is arguably the most noticeable component. Its main purpose is to pull air through the tower so that the water inside the tower and the surrounding air may exchange heat more easily. Airflow produced by the fan’s rotation aids in the removal of heat from the system and the evaporation of water. you can get cooling tower fan motor for hot water basins. Pick tower motor according to your tower structure.

The functions of a fan

- creates airflow for the exchange of heat by drawing air through the tower.

- helps the water evaporate, eliminating heat from the system

- guarantees effective cooling and adequate ventilation.

- can to be changed to control the tower’s cooling capacity

- runs constantly to keep temperatures at ideal levels

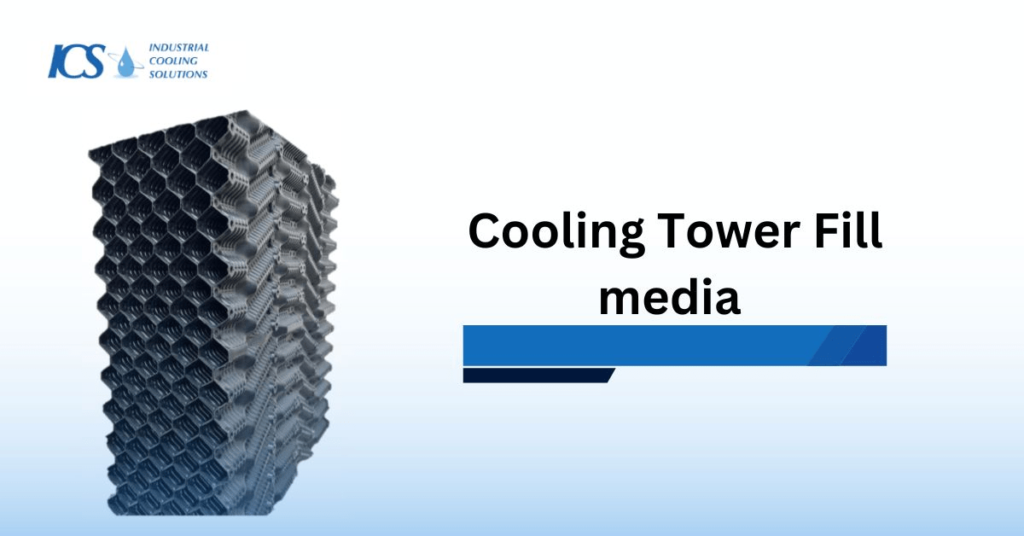

Fill Media

Materials called tower fill media are positioned inside the cooling tower to expand the amount of surface area that may be used for heat transmission. These materials are commonly stacked in a structure resembling a honeycomb and are composed of plastic or wood. Greater interaction between the water and the air travelling through the tower is made possible by the thin films that are formed as the water travels over the fill media. As a result, the heat exchange process operates more efficiently.

Functions of tower Fill Media

- Cooling tower fill expands the surface area that can be used to transport heat

- produces a turbulent air-water mixture for effective heat exchange.

- raises the effectiveness of the cooling tower by encouraging evaporation

- keeps water droplets from becoming entrained by creating a barrier that they must stick to.

- accessible in a range of materials, including metal, wood, and plastic

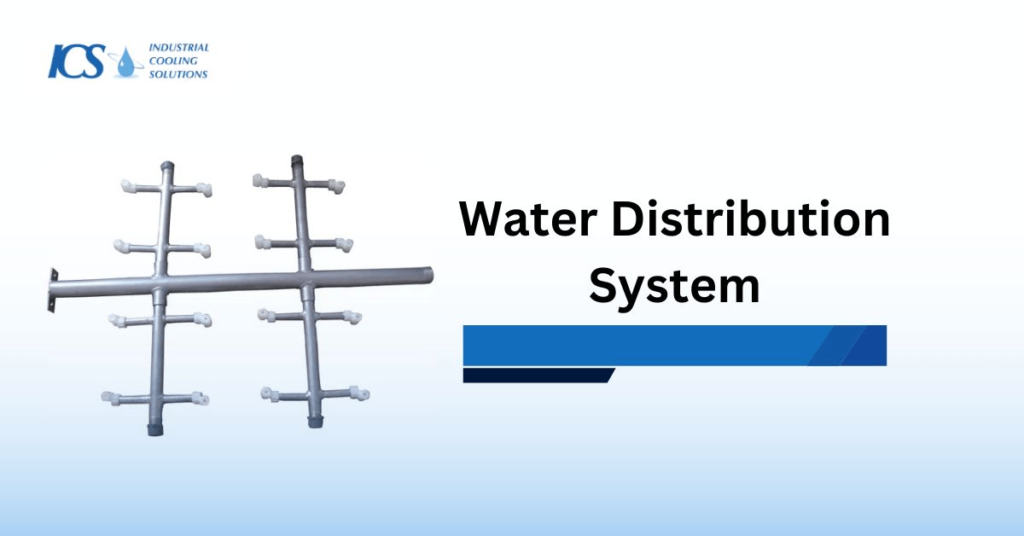

Water Distribution System

Water must be distributed uniformly throughout the cooling tower’s fill media using the water distribution system. Distribution basins, nozzles, and pipes are usually included. Water is dispersed or sprayed over the fill medium at the top of the tower after being pumped from the tower basin. Ensuring equal wetting of the fill material through proper distribution maximizes the effectiveness of heat transfer.

Function of the Water Distribution System

- uniformly distributes water across the fill medium to increase the contact surface

- guarantees that the fill media is uniformly moist for effective heat transfer.

- controls water flow rate to meet system cooling requirements

- reduces the amount of water wasted by preventing spills and uneven distribution

- include distribution basins, pipes, and pumps to control water circulation.

Drift Eliminators

The purpose of drift eliminators is to collect water droplets that are suspended in the air as they exit the cooling tower. Drift is the term for these droplets that may include pollutants or chemicals from the flowing water. Drift eliminators reduce water loss and stop environmental contamination by collecting drift and redistributing it to the tower basin.

Drift Eliminators Function

- Catch water droplets that are suspended in the air as they exit the cooling tower.

- Restoring collected water to the basin will help to minimize water loss and environmental contamination.

- Reduce drift losses to increase cooling tower efficiency.

- consist of mesh panels or baffles intended to catch and gather raindrops.

- assist in fulfilling legal obligations for pollution prevention and water conservation

Basin

Water gathers in the cooling tower’s basin, which is at its lowest point, before being fed back into the system. It helps to keep the water levels in the tower at the right levels and acts as a reservoir for the circulating water. Additionally, the basin gives silt and other detritus a place to settle out of the water, keeping the distribution system clear of obstructions.

Functions of basins

- gathers and holds the cooling tower system’s circulating water.

- offers a reservoir to keep the system balanced and the water levels at the right levels.

- stops clogs by allowing dirt and sediment to settle out of the water

- makes it easier to access areas for cleaning and maintenance tasks

- fitted with sensors to keep an eye on water quality and levels for operational control

Drift Collector

Drift collectors, which are similar to drift eliminators, are devices that gather water droplets as they leave the cooling tower. Usually, they are positioned above the fill medium to catch any drops that could evade the eliminators’ grasp. By reusing collected water in the tower basin, drift collectors contribute to the further reduction of water loss and environmental effect.

Functions of Drift Collector

- placed over the fill media in order to collect any water droplets that may come out of the eliminators

- returns collected water to the basin, thereby reducing water loss and its negative effects on the ecosystem.

- enhances drift eliminators to guarantee effective drift management in the cooling tower

- accessible in a variety of styles, including blade systems and mesh screens

- requires routine upkeep and inspection to guarantee correct operation.

louvers

The cooling tower’s outside is surrounded by louvres, which are used to regulate the airflow inside the structure. Operators can manage the rate of heat exchange by varying the position of the cooling tower louvers, which will affect how much air enters the tower. In order to ensure the tower operates efficiently, louvres also aid in preventing debris and foreign items from entering the structure.

Functions of cooling tower louvers

- Manage the cooling tower’s airflow to maximize heat exchange effectiveness.

- Adaptable to control the tower’s air intake volume according to cooling needs

- Stop wildlife, garbage, and foreign objects from entering the tower.

- Contribute to the cooling tower’s improved aesthetics and noise reduction

- offered in several configurations, including fixed and movable louvres

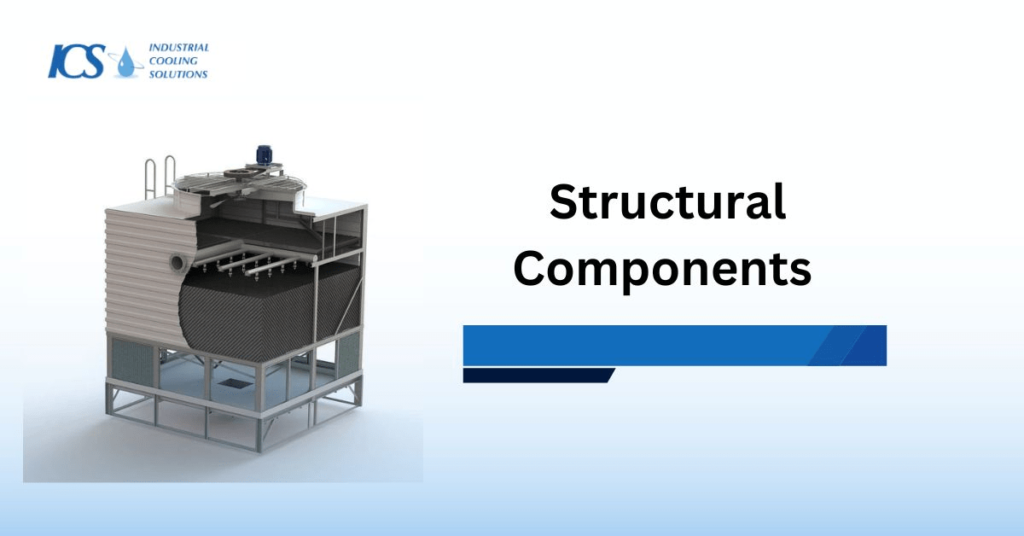

Structural Components

A cooling tower’s structural components comprise support beams, columns, and casing in addition to the functional parts already described. These parts give the tower stability and rigidity and guarantee its integrity in a variety of operational scenarios. For the cooling tower to operate safely and to avoid structural failure, structural component maintenance must be done correctly.

The structural elements’ functions

- Give the cooling tower stability and structural support.

- Withstand earthquake shocks, wind loads, and other environmental challenges

- consist of sturdy material support beams, columns, and framework

- made to endure difficult operating circumstances and hold its integrity throughout time

- require routine upkeep and inspection to guarantee lifespan and safe functioning.

From where you can get high quality cooling tower parts?

In many industrial operations, cooling towers are essential for dissipating heat and preserving ideal operating conditions. Comprehending the distinct components and their roles within a cooling tower is vital to guarantee optimal functioning and attain maximum efficiency. Through appropriate upkeep and observation of these elements, operators can guarantee the dependable and economical functioning of their cooling systems. You may get all cooling tower parts from ICS at a reasonable cost. Get in touch with us to receive our product catalogue. Also we are providing replacement cooling tower parts services for your cooling tower gearboxes.