Cooling towers are now necessary in many different sectors. Installing cooling towers has several advantages, including lower energy usage, lower costs, longer lifespans, and less maintenance. Many industrial units have chosen to put counterflow cooling towers in their facilities as a result of these benefits.

The need for correct cooling tower installation is growing, and as a result, counterflow industrial cooling tower manufacturers worldwide are working to give their clients high-quality solutions. Cooling tower functionality is influenced by several factors, including employing high-quality replacement parts when necessary and adhering to recommended maintenance procedures.

The drift eliminator is one of the most important parts of cooling towers. The drift eliminator is essential to the cooling towers’ correct operation. Let’s examine the cooling tower drift eliminators’ definition and its advantages.

Table of Contents (Cooling Tower Drift Eliminator)

What is a drift eliminator?

The cellular drift Eliminators maintain the optimal condition of the water recycling process. Its purpose extends beyond water conservation; it also stops the discharge of water tainted by chemicals into the environment.

Reducing water loss and emissions can be summed up as the main goal of a drift eliminator. It lowers the frequency of a cooling tower’s pressure drop and maintains the drift rate at a minimum.

How Does a Drift Eliminator Work?

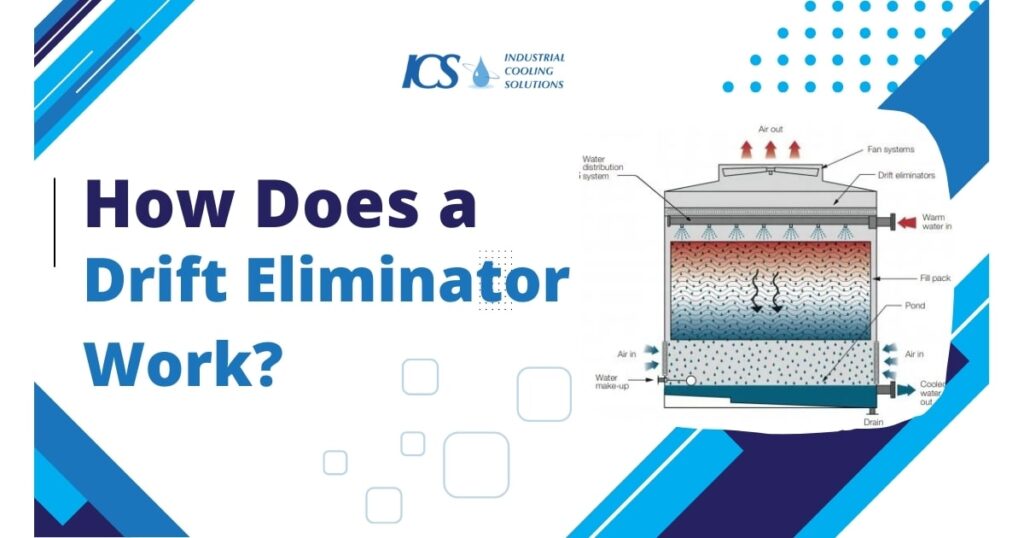

Drift eliminators’ primary job in evaporative cooling systems is to lessen—not completely eradicate, as the name implies—the escape of water droplets that are entrained in the cooling tower or evaporative condenser’s discharge air stream.

The eliminator foil or blade design changes the direction of the flow of air as it passes through the efficient drift eliminator. As a result, water droplets suspended in the airstream gather on the foil surfaces of the eliminator.

Instead of escaping in the discharge airstream, the droplets agglomerate and quickly acquire enough size and mass to surpass the velocity of the discharge airstream and drain back into the cooling tower.

Do Drift Eliminators Come with Every Cooling Tower?

Legally, in the UK, efficient drift eliminators “should be installed in all towers that have fans” (HSG274 Part 1), which means that all cooling towers and evaporative condensers need them in addition to low velocity, natural draught towers.

On the discharge side of a cooling tower, they can be found vertically in front of the heat transfer surface on a crossflow tower or above the cooling tower heat transfer surface and distribution system on a counterflow cooling tower.

What makes cellular drift eliminators necessary?

It is crucial to comprehend why reducing the escape of water droplets entrained in the air discharge is the goal of a drift eliminator.

Cooling tower drift eliminators offer other advantages outside just keeping people and the surrounding environment safe from escaping aerosols and water droplets from cooling towers or evaporative condensers.

In the worst situation, the drift eliminator offers the final line of defence against the spread of dangerous legionella bacteria, which are frequently discovered in water cooling systems, if the water treatment routine has failed.

By breathing in the legionella bacteria found in the cooling tower’s aerosol exhaust, one can get legionaires disease. Cellular Drift eliminators help conserve water in the cooling system by rerouting water droplets to the cooling tower. Since an efficient drift eliminators efficiency greatly influences the amount of water that can be saved, it’s critical to comprehend what the efficiency quoted means and how it relates to water savings.

What are the main benefits of drift eliminator?

Installing drift eliminators in cooling towers has various advantages, particularly in large-scale industrial plants. In addition to the benefits for the owners, there are environmental benefits as well. Let’s examine a few of the main advantages.

- It keeps the surrounding roads and fields from ice.

- Through the prevention of corrosion, it maintains the integrity of the pipe systems and electrical components.

- It is possible to avoid short circuits, which frequently result from broken electrical components.

- Drift eliminators guarantee a considerable decrease in the release of dangerous chemicals into the surrounding environment.

- Drift eliminators make large-scale water conservation practicable.

- Efficient Drift eliminators can lessen the frequent pressure decrease in the cooling tower’s water.

- Additional water treatment is not required because cooling towers are equipped with cellular drift eliminators.

- Additionally, specifically designed cooling tower’s lifespan is extended.

- It lowers energy usage considerably.

What causes Cooling Tower Drift?

Water released from cooling towers in addition to exhaust air is known as drift. Water droplets are entrained in the air as it passes through the cooling tower, especially as it goes through the distribution system. Typically, drift droplets have a diameter of 50–200 µm, or roughly the thickness of a human hair.

The escaping drift droplets can harm nearby equipment and the surrounding environment since they are made of the same chemical, bacterial, and particle components as the water that is cycling from the tower.

What Does a Cooling Tower’s Evaporation Loss Mean?

Utilising a cooling tower is a typical method of recovering waste heat from industrial processes, and in most of these processes, water is the coolant of choice.

A cooling tower’s fill or pack is filled with hot water that is supplied downward via spray nozzles. The goal of this packing material is to increase surface area in order to optimise air-hot water stream interaction. The water cools as air inside the tower rises because it absorbs the latent heat of vaporisation from the water.

Generally speaking, 1% of the total mass of water evaporates for every 5.5°C (10°F) drop in temperature.

Replacement of Drift Eliminator:

It’s not always necessary to replace drift eliminators with OEM models; in fact, depending on how well the current drift eliminators work, they could need to be upgraded. In any event, it’s a good idea to talk to a cooling tower specialist about your needs so you can find out what your options are in terms of performance, longevity, and simplicity of maintenance.

Cooling tower fans are frequently equipped with variable speed drives (VSDs) to lower the energy consumption of the fan motor. This implies that a variety of velocities will be needed for the eliminators to function. It is crucial that the eliminators are appropriate for every operational situation that the cooling tower may encounter.

Using inverter drives (VSDs) to adjust fan speed and hence vary tower velocities based on cooling requirements may also make sense. This has the potential to greatly reduce drift escape from cooling towers.

Last words:

The purpose of this article is to give a general overview of the performance traits and operation of

cellular drift eliminators in cooling towers and evaporative condensers. Please feel free to contact me with any specific queries you may have about your crossflow tower applications; I would be pleased to assist you. All cooling tower components are offered by Industrial Cooling Solutions (ICS). Make sure to check out our most recent ICS catalogue.