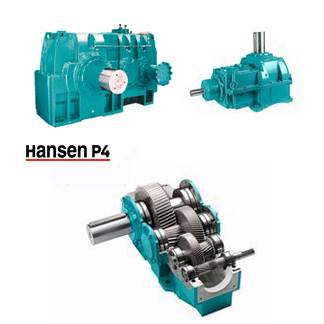

The P4 gearbox is available in 19 different sizes, ranging from 6kNm to 1100 kNm torque and with a power rating of up to 7,500kW. It is available with two, three or four-gear stages and reduction ratios between 6.3 and 630. There is also an option of a solid or hollow low speed shaft and parallel or right-angle shaft arrangement to cater for specific industrial requirements. Also a single stage version for applications such as pumps is available.

- Compact gearbox

- Operate in open air and/or humid environment

- External loads acting directly on the low speed shaft

- Low noise & vibration levels

- Customized output shaft

- Reliable low maintenance drive

- Complete drive packages

Product description

The Hansen P4 gear units are customized to the specific needs of the cooling tower industry and fully comply with the Cooling Tower Institute specifications.

P4 Multistage Units

Mounting pads for motor base on the top of the unit.

Mounting pads for motor base on the top of the unit.- Strong oval lifting lugs for easy handling.

- Standard fixation points for easy mounting of accessories on the side of the gearbox (e.g. cooling systems).

- Provisions for crowbar on smaller housing for easy alignment during installation.

- Provision for easy removal of covers to perform service on the spot when needed.

- The rounded external design ensures a smooth surface without dirt or moisture retaining cavities.

- Provision for complete oil drainage = drain plug at lowest position and system of internal drain holes and channels.

- Central filling connected to internal oil distribution system to ensure all parts are lubricated before start-up.

- Large inspection cover with re-usable O-ring.

- Horizontal split housing for easy maintenance.

The extended bearing span of the low speed shaft has been standardized to meet the particular needs of these applications: the extended bearing span increases the dynamic stability of the gear unit. The unit’s low speed shaft bearings are selected to handle the high axial loads, i.e. the axial thrust from the fan on the low speed shaft. The lubrication system is adapted to very low operation speeds and to windmilling conditions. The overall design of this series of gear units fully complies with the Cooling Tower Institute specifications.

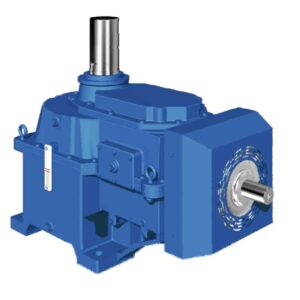

For the wet cooling tower drives, we now offer a range of 11 bevel helical gear unit sizes up to 100 kNm, which allows a more accurate selection. They are all well protected for operation in a very humid environment. The increased distance between the propeller and the high speed input shaft reduces vibrations. A motor can be connected to the outside of the cooling tower using an all-metal disc coupling at the high-speed shaft.

Mounting pads for motor base on the top of the unit.

Mounting pads for motor base on the top of the unit.