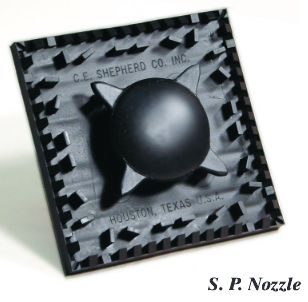

The C. E. Shepherd Square Pattern Nozzle, or SP Nozzle, maximizes water contact to the heat transfer media (fill). Water exits the nozzle in a uniform downspray of fluidized water particles in a large surface to volume ratio.

Unlike nozzles that disperse water in a circular pattern, the SP Nozzles is configured to mirror the footprint of straight sided industrial cooling towers, assuring coverage for all areas of the fill while significantly reducing water shedding on the side, partition and end walls.

With proper installation, the SP Nozzles are pitched to produce overlapping individual sprays from adjacent nozzles. This design, in concert with the engineered spray of uniformly sized water droplets, achieves ideal distribution over the fill and in turn, assures maximum heat transfer within the fill system itself.

While snap-together nozzle designs often fail at the splash plate creating heavy streams of water that erode PVC fill and negatively impact the thermal efficiency of the tower, the Shepherd SP Nozzle is welded at each connection point between the SP Nozzle body and the target plate.

This superior design assures long-term durability of the nozzle, minimizes erosion of the fill and contributes to tower efficiency. Customize the SP Nozzle for outstanding performance in a myriad of configurations with our line of accessories. Color-coded, interchangeable orifices make flow adjustment a snap.

Pipe and wood thread extensions and saddle pipe adaptors, available with your choice of male/female threaded ends, accommodate virtually any size lateral line.

Adapters:

Adapters: