Product description

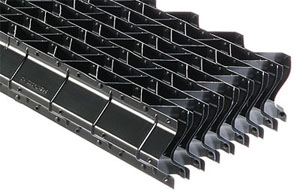

XF150MAx Crossflow Cellular Drift Eliminators are specifically designed to maximize drift removal efficiency in crossflow tower applications by providing an upward flow path and discharge angle of 40-55° from horizontal (depending on installation angle) and molded-in drainage channels that direct the collected drift back to the wet section of the tower even when impacted by water spray. The modules are constructed of a series of sinusoidal-shaped, corrugated PVC sheets that are mechanically assembled to mating sinusoidal structural waves, forming closed cells. These cells force the drift droplets being carried in the leaving airstream to make three distinct changes in direction. These forced changes to the air flow create centrifugal forces on the droplets that remove them from the air stream by causing them to impact the module walls, collect, and drain back to the wet section of the cooling tower.