Sometimes, the machines we use daily need a little TLC, and we aren’t talking about the classic 90s R&B group. When you think about the good fan, your cooling tower deserves all the tender love and care you can spare. Without your tower, whatever industry you work in would not be possible.

While the industrialization of our nation was a good thing overall, it also presented us with a new problem in the form of excess heat. Heat, for the most part, is not something that most people think about on a given day; however, heat can be a highly destructive force for individuals involved in industrial-related fields.

Traditionally, heavy machinery does not like heat. That isn’t to say that tower fans cannot operate under conditions that, to a human, would seem excessively hot; it simply means that they do not like having to deal with any more heat than is necessary.

In today’s post, we here at Industrial Cooling Solutions Inc. wanted to go over an important subject—when is it time to replace the fan blades in your industrial best tower fans cooling tower?

These tower fans cooling tower play a major role in eliminating heat, and it is important that you, as the operator, know when it is the right time to retire one fan and replace it with another. Keep reading below to learn more.

Understanding Cooling Tower Fans:

The cooling process is greatly aided by remote control cooling tower fans, which are crucial for cooling tower systems. Their main job is to rotate cool air and transfer heat from the water inside the tower to the surroundings easier. The fans cooling tower provides effective cooling and convenient remote control air purifiers and the optimum flowing water temperature by generating a constant flow of cool air.

Maintaining the best cooling tower fan performance requires routine maintenance. Tower fans cooling tower may gather dust, dirt, or mineral deposits over time, reducing their effectiveness and airflow.

Fan blades, motors, and bearings should be cleaned and inspected regularly to guarantee smooth operation and avoid problems like imbalance or damage. The best tower fans ‘ lifespan is increased by proper lubrication, which also lowers friction.

Monitoring fan belts, examining electrical connections, and carrying out routine performance evaluations are crucial features to spot and fix possible issues early. Making routine maintenance a top priority enables you to maximize the effectiveness and dependability of your remote control cooling tower fans, thus improving the performance of your cooling system.

Are You a Fan of Your Fan?

When it comes to manage industrial cooling towers, many pieces must work together to ensure the tower is effectively doing its job. The water pump must be in proper working order to ensure that the necessary amount of liquid is pumped into the tower system; the fill media must be properly placed and cleaned to reduce the amount of lost water.

Also, the entire tower must be free from scale build-up to ensure that the maximum amount of heat is being mitigated as possible. While all of these details must be taken care of to ensure that the tower performs as optimally as possible, it is especially important to ensure that the fan inside the cooling tower is in the best working condition possible.

Without the fan, it doesn’t matter if all of the other components of the tower are perfect; the water will not be cooled properly, and, as a result, the tower will not be able to rotate cool breeze and perform its job.

Signs of a Faulty Cooling Fan:

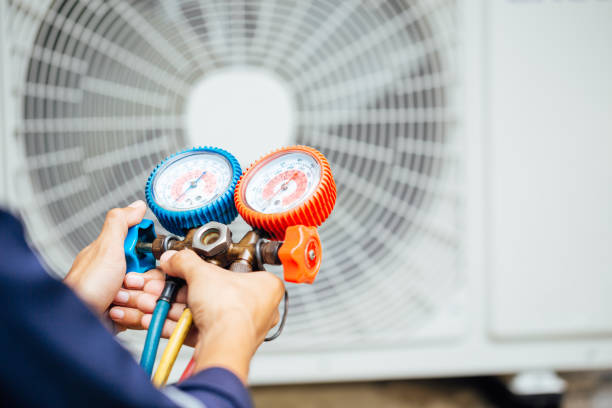

Maintaining the effectiveness and functioning of your cooling system depends heavily on the cooling tower fan. It ensures your equipment runs smoothly by assisting with gentle air circulation and heat dissipation.

However, fans cooling tower might have problems influencing their performance like any mechanical part. Understanding the symptoms of a failing oscillating tower fan is essential for avoiding expensive failures and ensuring the lifespan of your cooling tower. Read further for the following warning signs:

Inadequate airflow and decreased cooling effectiveness:

The system’s cooling efficiency and air speed show malfunctioning cooling tower fans. If you observe that the cooling capacity is not operating at the required levels or that the air speeds from the tower are weaker than usual, there might be a problem with the fan.

Strange sounds and vibrations:

Unusual sounds or vibrations during operation are another sign of defective remote control cooling tower fans. These sounds of tower fans might be loud, erratic vibrations, or rattling or grinding. Such fan noises and vibrations may indicate a motor problem, broken or loose fan blades, or misalignment.

Fluctuating temperatures or overheating:

The system may experience overheating problems due to a broken fans cooling tower. It may indicate that the cooling fan is not properly circulating the air to provide proper cooling if you find that the temperature levels in the tower are regularly higher than usual or if you detect temperature variations. you can use an air purifier.

Extravagant energy usage:

Energy use may rise as a result of broken cooling tower fans. If there is a sudden boost in energy demand with no other explanation, the fan may not be working as accurately as it should. This increased energy use may result in greater electricity costs and less effective cooling.

Visual inspection and physical damage indicators:

It is crucial to examine the oscillating tower fan visually. Look for physical damage indicators, such as twisted or broken fan blades, loose connections, or wear-and-tear indications. Visual clues can offer insightful information about the state of the fan and assist in spotting possible problems.

Troubleshooting and Maintenance Tips for fans cooling tower:

Proactive troubleshooting and routine maintenance are crucial for preserving the functionality and durability of your best tower fan. You may solve common fans problems by becoming familiar with a few straightforward troubleshooting methods and implementing efficient maintenance procedures.

So let’s learn how to effectively troubleshoot and control your oscillating tower fan to guarantee that it operates at its peak efficiency.

Simple methods for troubleshooting typical cooling tower fan issues:

There are straightforward troubleshooting procedures you may use when dealing with typical oscillating tower fan issues before enlisting expert help. Inspecting fan electrical connections, verifying appropriate alignment and balance of the fan, checking for loose or broken fan belts, and removing any dirt or obstructions from the area around the fan are a few examples.

You can fix simple difficulties and get the fan working again by taking care of these frequent problems.

Routine maintenance, such as belt replacement and lubrication:

The best functioning of your oscillating tower fan depends on routine maintenance. This also entails routinely lubricating the motor and fan bearings to lessen friction and increase longevity.

Fan belts must be regularly inspected and promptly replaced to avoid belt slippage and preserve correct functioning. pickup the fan routine maintenance in your maintenance program; it may maximize your cooling tower fan’s effectiveness and lifespan.

Cleaning and buildup prevention advice for the fan system:

For the oscillating tower fan system to remain effective, debris collection must be avoided. Clean the fan housing and blades often to eliminate dirt, abnormal fan speeds, dust, or debris obstructing airflow.

Pick up the proper cleaning equipment and methods to prevent harming the fan components. To further reduce the chance of clogging and potential damage, consider installing safety screens or filters to stop big debris from entering the fan system.

Options for expert maintenance and repairs:

While many fans cooling tower problems may be resolved with straightforward troubleshooting and routine maintenance, it is essential to have access to expert maintenance and repair solutions. Professional technicians have the knowledge and specialized equipment to identify and fix complicated issues quickly.

They may conduct thorough examinations, make sophisticated repairs, and offer maintenance services designed for your cooling tower fan system. Pickup the experienced fan knowledge, that guarantees your oscillating tower fan to gets the maintenance and care it needs to perform at its peak.

When do you need to replace your cooling tower fan?

However, how should a person know when to replace a failing personal tower fan?

Below, we have listed some points to consider when deciding whether or not it is the right time to change your cooling tower fan.

Age:

The first thing you must consider when deciding whether or not to replace the fan in your industrial cooling tower is how old the fan is. Was it installed recently, say two or three years ago, or is it the fan that came with the tower when it was installed over a decade ago?

fans cooling tower are designed to work for a long time; however, like any machine component, they are not designed to last indefinitely. If your personal tower fan is over five years old, we suggest you inspect it carefully to ensure it still depends on the task it was built for.

Damage:

Piggybacking off of the first point, it is important to inspect your fan’s blades and body regularly to make sure that fans cooling tower have not been structurally compromised. When inspecting the fan, look for cracks, dents, chips, or other structural damage.

While a small crack or chip might not seem like an efficient deal in the scheme of things, any compromises in the structural integrity of your system’s fan can result in the fan ripping itself apart at an inconvenient time.

If you notice that your fan has damage near the center (the area where the blades of the fan meet), you must replace your fan. The rotational fan speed at which these tower fans operate could cause the fan’s blades to come off, abnormal fan speeds, fan damaging fill material or, in more extreme cases, causing damage to the tower’s walls.

Type of Fan:

This tip is more a matter of opinion, but considering we are experts in industrial cooling towers, our opinions are valid. Traditionally, fans cooling tower were made from aluminum.

These aluminum tower fans were lightweight, durable, and, for the most part, the best option for their intended application. Unfortunately, these aluminum fans had a few weaknesses. The most glaring weakness was that the fan’s blades had to be attached to a central hub.

Where the blades were attached to the central hub became a major weak spot for the fans and resulted in stress fractures that could cause the blades to rip off at high fan speed. Luckily, this issue has largely been resolved with the introduction of FRP fan blades.

These tower fans are molded into a single piece and made from a hard, durable plastic much less likely to break apart than traditional aluminum blades. If your cooling tower does not use FRP fan blades, we highly recommend you consider making the switch. Not only are FRP fan blades more efficient at what they commit, but they also have a much longer lifespan.

Wrapping Up:

In conclusion, monitoring the condition of your energy-efficient, personal tower fans is essential for preserving your cooling system’s efficacy and efficiency. You can ensure your cooling tower fan stays in top shape by being aware of the features, speeds & symptoms of a failing slim profile cooling tower fans, abnormal fan speeds, comprehending its function in the cooling rotate process, and putting regular maintenance procedures into practice.

Red flags, including inadequate ventilation, strange sounds, overheating, excessive energy use, air purifier, or obvious physical damage, shouldn’t be disregarded. Remember that a well-maintained energy efficient, best tower fan adjust cooling effectiveness, lowers your energy expenses, and helps you prevent expensive repairs.

So, take the necessary actions to manage or control your cooling tower fan running smoothly and profit from a cooling system in good working order. Keep cool and use your remote control cooling tower fans in a comfortable approach easily.

Best Platform for Tower Fans’ Maintenance:

Are you seeking reliable and effective remote control cooling tower fans repair and maintenance services?

There is no need to look beyond ICS (Industrial Cooling Solutions)! We are committed to adjust & maintain your cooling tower fans’ best performance and energy efficiency. From motor troubles to airflow limits, our team of skilled experts is skilled at diagnosing and fixing many cooling tower fans problems.

Why ICS is a leading platform?

To increase the lifespan of your cooling tower fans and avoid expensive rotates breakdowns, we provide regular inspections, cleaning, lubricating, and other essential services. ICS can manage your cooling tower fans operating without a hitch. To schedule a consultation and discover the ICS difference, Pickup the idea to contact us immediately!

Prevent operational disruption due to malfunctioning cooling tower fans. Schedule your tower fans’ maintenance and turn on your repair services with ICS immediately to get a dependable, effective, cooling, gentle breeze all year in a comfortable way!