Cooling tower is a common sight in many parts of the world. They are used for a variety of purposes. But what exactly is a cooling tower? What are its components, and how do they work together?

This article will discuss hybrid cooling towers and cooling tower components in detail and how they are used.

Cooling Tower Parts and their Functions:

A cooling tower is a type of tower that is used to cool water or other fluids. Cooling towers are often used in power plants, chemical plants, refineries and most industrial process plants and factories, where they are used to cool water heated by machinery. Cooling tower works by using the evaporation of water to remove heat from the water.

The main component of a cooling tower is the itself. The cooling tower is typically made of concrete, wood, or fibreglass. The cooling tower is also equipped with mechanical equipment consisting of fans, gears, driveshafts & motors, which help to circulate air throughout the cooling tower. The above mechanical draft and equipment help to evaporate the water, which in turn helps to cool the water.

Let’s take a closer look at all the important cooling tower parts.

Instrumentation and Electrical Systems:

A cooling tower’s instrumentation and electrical systems are responsible for monitoring and controlling the operation of the cooling tower’s water distribution system.

Cooling Tower Fan Motor:

When the cooling tower motor is in operation, the fan motor is responsible for the cooling flow and powering the fan and cooling tower part. The fan motor can be single speed, two-speed or inverter VFD driven motors.

Nozzles:

Cooling tower nozzles are used to spray water onto the fill media. The water sprayed from cooling tower nozzles onto the cooling tower fill media helps evaporate and cool the hot water.

Cooling Tower Float Valve:

As the name float distribution or float valves suggest, a cooling tower float valve distributes water evenly throughout the cooling tower.

Drive Shafts:

Drive shafts are used to connect the cooling tower motor to the fan.

Gear Box:

The gearboxes have many speed ratios and reduce the speed of the motor for optimal fan speed in each applicati

on. From time to time, part of the cooling tower gearboxes will need to be rebuilt or replaced.

Cooling Tower Louvers:

Cooling tower louvers help to eliminate the splashout of hot water from where the air enters the cooling tower.

Fan Deck:

The fan deck is the working surface of the cooling tower motor, which gives you access to the cooling tower mechanicals and entry to the fill pack.

Water Distribution Piping:

Water distribution piping is used to distribute water evenly throughout the cooling tower’s distribution system.

Cooling Tower Fans:

Cooling and cooling tower fans help to circulate air throughout the cooling tower.

Cooling Tower Structure:

This is the framework that supports the cooling tower structure & can be made of fire-retardant FRP, concrete, wood or steel. The lifecycle of the structure depends upon the materials of construction and the care and maintenance of the materials used.

Cold Water Basin:

The cold water basin is where the cooled water is collected and directed to the pump suction line.

Cooling Tower Drift Eliminators:

Cooling tower drift eliminator help to remove any droplets of water that are not evaporated.

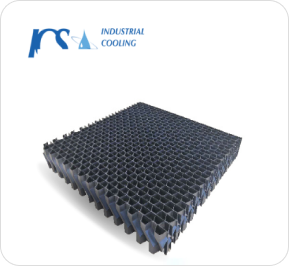

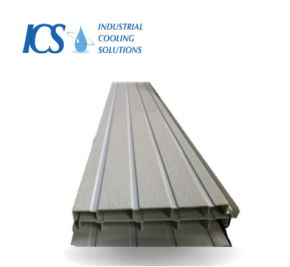

Cooling Tower Fill Media:

The cooling tower fill media is the area where the water is mixed with the fan air flow and the main heat transfer takes place. It’s deeply important to have the right type of cooling tower fill media in order to maintain good thermal efficiency and maximize the efficiency of the cooling tower.

As you can see, there are many parts that make up a cooling tower. Each part has an important role to play in the operation of the cooling tower.

In order to keep your cooling tower in good working condition, it’s important to understand all the different part of the cooling tower parts diagram and how they work together.

How Does Cooling Tower Work?

Cooling tower uses the water droplets’ evaporation to remove heat from the water. As the water droplets evaporates, it takes heat away from the water. This process helps to cool the water.

The cooling process works like this:

- Warm water is sprayed onto the fill media.

- The evaporation process cools the warm water.

- The cooled water is collected in the cold water basin.

- The cooled water is circulated back to the machinery.

The cooling process is repeated over and over again to maintain the desired process temperature.

What is Cooling Tower Fill Material?

The fill material is one of the most important parts of a cooling tower. The fill material helps to increase the surface area of the cooling tower and maximizes the airflow to the water contact, which in turn helps to increase the evaporation rate.

Many types of fill material can be used in a cooling tower. The most common type of fill material is PVC. PVC is a durable material that is resistant to corrosion. Some other types of fill material that are used in cooling towers include:

- PP – Polypropylene

- Fiberglass

- Stainless steel

- Wood

The type of cooling tower packing amount of fill material that you use will depend on the specific needs of your cooling tower.

What are the fillings of cooling tower?

The fillings in cooling towers are essential for maximizing the contact area between the air and the water being cooled. They are designed to enhance heat transfer and increase the efficiency of the cooling process.

The fillings are typically made of plastic or other durable materials and are structured to create a large surface area.

Two main types of fillings commonly used in cooling towers are splash fill and film fill.

Splash Fill:

Splash fill consists of slats or bars arranged in a staggered pattern. When the water enters the cooling towers, it is distributed over the splash fill, which breaks the water into small droplets.

As these droplets fall through the open circuit wet cooling tower, they come into contact with the upward-flowing air, promoting efficient heat transfer. The splashing action also helps to increase the mixing of air and water.

Film Fill:

Film fill comprises thin, closely spaced sheets or channels that allow water to form a thin film as it flows over them. This type of filling creates a large surface area for heat exchange, maximizing the contact between the water and the air.

The film fill design facilitates the formation of a thin water film, which increases the exposure of water to the air, resulting in improved heat transfer efficiency.

Both splash fill and film fill play a crucial role in cooling tower operation by facilitating heat exchange between the water and the air.

The choice of fill type depends on factors such as the specific cooling requirements, the design of the cooling towers, and the environmental conditions in which the tower operates.

How are Cooling Tower Components Built?

Cooling towers can be built in a variety of different ways. The two-counterflow or flow cooling tower is the most common type of cooling tower.

Counter flow cooling towers are the most efficient type of cooling tower & therefore, the most cost-effective design.

The second type of cooling tower is the crossflow cooling tower. Crossflow are best suited for dirty water scenarios where the water conditions are unsuitable for film-type fill.

The Bottom Line

Cooling tower is an important part of many types of machinery. They work by using the evaporation of water to remove heat from the water.

In order to keep your cooling and tower parts in good working condition, it’s important to have a good understanding of all the different parts of cooling tower and how they work together.

If you’re in need of a new cooling tower, a cooling tower upgrade or replacement cooling tower parts and functions for your industrial process, be sure to contact Industrial Cooling Solutions.

We offer various cooling towers that are sure to meet your needs. We also offer a wide range of replacement cooling tower parts and accessories, so you can keep your cooling tower in good working condition.

THE COOLING TOWER COMPONENTS:

HOW DO THEY WORK?

Cooling tower is a common sight in many parts of the world. They are used for a variety of purposes. But what exactly is a cooling tower? What are its components, and how do they work together?

This article will discuss hybrid cooling towers and cooling tower components in detail and how they are used.

Cooling Tower Parts and their Functions:

A cooling tower is a type of tower that is used to cool water or other fluids. Cooling towers are often used in power plants, chemical plants, refineries and most industrial process plants and factories.

HOW DO THEY WORK?

Cooling Tower Parts and their Functions:

A cooling tower is a type of tower that is used to cool water or other fluids. Cooling towers are often used in power plants, chemical plants, refineries and most industrial process plants and factories, where they are used to cool water heated by machinery. Cooling tower works by using the evaporation of water to remove heat from the water.

The main component of a cooling tower is the itself. The cooling tower is typically made of concrete, wood, or fibreglass. The cooling tower is also equipped with mechanical equipment consisting of fans, gears, driveshafts & motors, which help to circulate air throughout the cooling tower. The above mechanical draft and equipment help to evaporate the water, which in turn helps to cool the water.

Let’s take a closer look at all the important cooling tower parts.

Spare Parts

Instrumentation and Electrical Systems:

A cooling tower’s instrumentation and electrical systems are responsible for monitoring and controlling the operation of the cooling tower’s water distribution system

Cooling Tower Fan Motor

Cooling Tower Nozzles

Cooling Tower Louvers

Cooling Tower Float Valve

Cooling Tower Gear Box

Cooling Tower Fan Deck

Water Distribution Piping

How Does Cooling Tower Work?

How Does Cooling Tower Work?

Cooling tower uses the water droplets’ evaporation to remove heat from the water. As the water droplets evaporates, it takes heat away from the water. This process helps to cool the water.

The cooling process works like this:

1. Warm water is sprayed onto the fill media.

2. The evaporation process cools the warm water.

3. The cooled water is collected in the cold water basin.

4. The cooled water is circulated back to the machinery.

5. The cooling process is repeated over and over again to maintain the desired process temperature.

What is Cooling Tower Fill Material?

The fill material is one of the most important parts of a cooling tower. The fill material helps to increase the surface area of the cooling tower and maximizes the airflow to the water contact, which in turn helps to increase the evaporation rate.

Many types of fill material can be used in a cooling tower. The most common type of fill material is PVC. PVC is a durable material that is resistant to corrosion. Some other types of fill material that are used in cooling towers include:

1. PP – Polypropylene

2. Fiberglass

3. Stainless steel

4. Wood

The type of cooling tower packing amount of fill material that you use will depend on the specific needs of your cooling tower.

What are the fillings of cooling tower?

The fillings in cooling towers are essential for maximizing the contact area between the air and the water being cooled. They are designed to enhance heat transfer and increase the efficiency of the cooling process.

The fillings are typically made of plastic or other durable materials and are structured to create a large surface area.

Two main types of fillings commonly used in cooling towers are splash fill and film fill.

Splash Fill:

Splash fill consists of slats or bars arranged in a staggered pattern. When the water enters the cooling towers, it is distributed over the splash fill, which breaks the water into small droplets.

As these droplets fall through the open circuit wet cooling tower, they come into contact with the upward-flowing air, promoting efficient heat transfer. The splashing action also helps to increase the mixing of air and water.

Film Fill:

Film fill comprises thin, closely spaced sheets or channels that allow water to form a thin film as it flows over them. This type of filling creates a large surface area for heat exchange, maximizing the contact between the water and the air.

The film fill design facilitates the formation of a thin water film, which increases the exposure of water to the air, resulting in improved heat transfer efficiency.

Both splash fill and film fill play a crucial role in cooling tower operation by facilitating heat exchange between the water and the air.

The choice of fill type depends on factors such as the specific cooling requirements, the design of the cooling towers, and the environmental conditions in which the tower operates.

How are Cooling Tower Components Built?

Cooling towers can be built in a variety of different ways. The two-counterflow or flow cooling tower is the most common type of cooling tower. Counter flow cooling towers are the most efficient type of cooling tower & therefore, the most cost-effective design.

The second type of cooling tower is the crossflow cooling tower. Crossflow are best suited for dirty water scenarios where the water conditions are unsuitable for film-type fill.

The Bottom Line

Cooling tower is an important part of many types of machinery. They work by using the evaporation of water to remove heat from the water.

In order to keep your cooling and tower parts in good working condition, it’s important to have a good understanding of all the different parts of cooling tower and how they work together.

If you’re in need of a new cooling tower, a cooling tower upgrade or replacement cooling tower parts and functions for your industrial process, be sure to contact Industrial Cooling Solutions.

We offer various cooling towers that are sure to meet your needs. We also offer a wide range of replacement cooling tower parts and accessories, so you can keep your cooling tower in good working condition.