สถานประกอบการอุตสาหกรรมและเชิงพาณิชย์หลายแห่งต้องการหอทำความเย็นเป็นส่วนประกอบที่จำเป็น หน้าที่หลักคือการขจัดความร้อนส่วนเกินจากการดำเนินงานทางอุตสาหกรรมหรือระบบปรับอากาศ หอหล่อเย็นใช้กลไกการถ่ายเทความร้อนและการระเหยอย่างมีประสิทธิภาพเพื่อให้บรรลุเป้าหมายนี้ อย่างไรก็ตาม หอทำความเย็นจำเป็นต้องก่อสร้างเพื่อให้ทำงานได้อย่างถูกต้อง บทความนี้จะบอกความสำคัญของฟิลในหอทำความเย็น

ฟิลหอทำความเย็นหมายถึงอะไร?

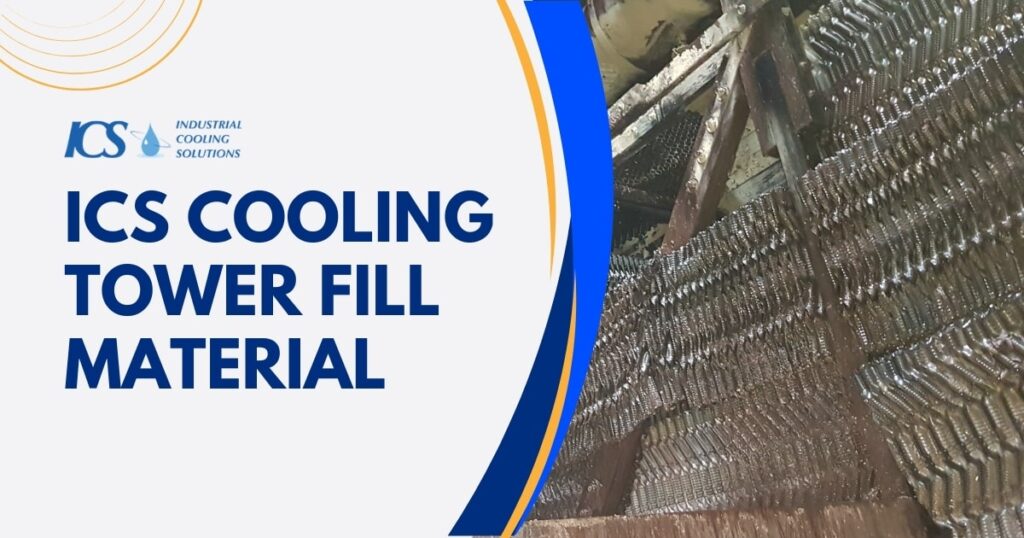

วัสดุที่ใช้อุดภายในหอทำความเย็นเรียกว่าฟิล ฟิลหอทำความเย็นเป็นส่วนสำคัญของหอคอยเพราะจะทำให้น้ำมีพื้นที่ผิวไหลผ่านได้มาก และช่วยส่งความร้อนจากน้ำสู่อากาศ โดยทั่วไปจะประกอบด้วยพีวีซีหรือพลาสติกประเภทอื่น โดยมีวัตถุประสงค์เพื่อให้ไส้กรองมีความแข็งและน้ำหนักเบา

วัตถุประสงค์ของฟิลหอทำความเย็น

การเพิ่มพื้นที่ผิวของน้ำที่สัมผัสกับอากาศเป็นเป้าหมายหลักของฟิลหอทำความเย็น น้ำจะกระจายไปเป็นแผ่นฟิลบางๆ ขณะที่น้ำไหลผ่านฟิล ทำให้สัมผัสกับอากาศได้สูงสุด พื้นผิวสัมผัสยิ่งมากยิ่งเป็นส่วนสำคัญที่จะเพิ่มปริมาณความร้อนที่จะส่งผ่านจากน้ำสู่อากาศได้สูงสุด

ขณะที่น้ำไหลผ่านหอคอย เข้าสู่วัสดุฟิลจะทำให้เกิดการกระจายตัวของน้ำที่ดี การกระจายตัวนี้ช่วยให้แน่ใจว่าทุกส่วนของน้ำสัมผัสกับอากาศและคายความร้อน ด้วยเหตุนี้ ประสิทธิภาพโดยรวมของหอทำความเย็นจึงเพิ่มขึ้น

การลดปริมาณน้ำที่สูญเสียไปจากการระเหยเป็นประโยชน์อย่างมากในฟิวหอทำความเย็น ปริมาณน้ำที่ระเหยจะลดลงเมื่อฉีดน้ำลงบนวัสดุฟิล เนื่องจากน้ำถูกกระจายออกจากกัน สิ่งนี้มีความสำคัญเนื่องจากในหอทำความเย็น การระเหยอาจเป็นแหล่งสำคัญของการสูญเสียน้ำ การลดการสูญเสียนี้สามารถลดค่าใช้จ่ายในการดำเนินงานได้

ฟิลหอทำความเย็นแบ่งได้สองประเภท

สแปลชฟิล:

สแปลชฟิลทั้งแบบตัดขวางหรือขัดขวางการไหลของน้ำ ดังที่ชื่อบอกเป็นนัย ทำให้เกิดการกระเซ็น

สแปลชฟิล ใช้ชั้นแถบแนวนอนที่จะแยกน้ำออกเป็นหยดเล็กๆ เมื่อสัมผัสกัน การระเหยจะเกิดขึ้นได้เร็วยิ่งขึ้นเมื่อมีหยดมากขึ้น (และเล็กลง) สแปลชฟิลมักทำจาก PVC เนื่องจากมีความน่าเชื่อถือ (และใช้งานได้จริง) มากกว่าไม้ กล่าวกันว่าเป็นสารที่ค่อนข้าง “เปียกได้” ทำให้ของเหลวกระจายไปทั่วได้ง่าย พีวีซียังมีอายุการใช้งานยาวนาน กันน้ำ และเคลือบด้วยน้ำได้ง่ายอีกด้วย สแปลชฟิลมักนิยมใช้สำหรับการใช้งานที่มีคุณภาพน้ำไม่ดีอย่างสม่ำเสมอ รักษาประสิทธิภาพไว้เนื่องจากประเภทนี้ต้องการพื้นที่ที่อาจสะสมสิ่งสกปรกหรือวัสดุอื่น ๆ ลงสู่น้ำ

ฟิล์มฟิล:

รูปแบบฟิลของหอทำความเย็นที่พบมากที่สุดเป็นอันดับสองเกี่ยวข้องกับการวางแผ่นพีวีซีที่มีพื้นผิวเปราะบางที่อยู่ติดกัน เพื่อให้น้ำกระจายระหว่างแผ่นเหล่านั้น ทำให้เกิดฟิล์มชนิดหนึ่ง Channel หรือ flute เป็นชื่อที่ตั้งให้กับพื้นผิวพีวีซี ร่องอาจจัดเรียงได้ไม่จำกัด ทั้งแนวตั้ง แนวนอน ลอนขวาง และอื่นๆ แทนที่จะปล่อยให้น้ำไหลเข้าเป็นเส้นตรง คลองส่งน้ำได้อย่างมีประสิทธิภาพในการเดินทางที่ยืดเยื้อซึ่งเต็มไปด้วยโค้งและคดเคี้ยว ชั้นที่ได้จะเปราะบางและระเหยเร็วเพราะน้ำสามารถเคลื่อนที่ได้หลายทาง

ฟิล์มฟิลอาจเป็นทางเลือกที่เหมาะสมที่สุดเนื่องจากอัตราการระเหยที่รวดเร็ว อย่างไรก็ตาม ฟิลเหล่านี้ไม่ใช่ตัวเลือกที่ดีที่สุดในการใช้งานกับน้ำที่มีความเข้มข้นสูงจากเศษหรือสิ่งสกปรก หากเศษสิ่งสกปรกมีขนาดไม่เหมาะสม ก็สามารถอุดตันร่องฟันได้ง่าย หากต้องการใช้ฟิล์มฟิล วิธีแก้ไขปัญหานี้คือการเพิ่มขนาดร่อง/ช่อง ทำให้เศษสิ่งสกปกอุดตันฟิลได้ยากขึ้น

คุณภาพน้ำถือเป็นข้อกังวลที่สำคัญ ในกรณีนี้ ฟิลแบบอื่น เช่น ฟิลแบบแท่ง อาจมีประสิทธิภาพมากกว่า ฟิลแท่งช่วยในการแปรรูปน้ำที่มีมลพิษสูงได้มีประสิทธิภาพกว่าน้ำที่สะอาดกว่า

หลักการทำงานของฟิลหอทำความเย็น

มาตรวจสอบกัน; หลักการการของฟิลหอทำความเย็น วัตถุประสงค์ของการใช้ฟิล์มฟิลพีพี คือการทำให้ถังเย็นลง น้ำที่ไหลผ่านแผ่นฟิลแบบแผ่นจะมีพื้นที่ผิวที่ใหญ่กว่ามาก น้ำร้อนจะเย็นลงอย่างรวดเร็ว นี่คือเหตุผลของ “ฟิล์มฟิล” ในชีวิตประจำวัน แนวคิดแนวทางการดำเนินงานคือ:

น้ำร้อนจะถูกทำให้เย็นลงอย่างรวดเร็วด้วยพื้นที่ผิวที่ใหญ่ขึ้น ต้องขอบคุณฟิลหอทำความเย็น ซึ่งใช้แผ่น อากาศ และตัวกลางในฟิล์มฟิลที่ยาวมาก เมื่อน้ำเย็นลงแล้ว ก็จะถูกปั๊มลงในภาชนะเพื่อทำให้น้ำเย็นลงมากขึ้น ในขณะเดียวกัน น้ำร้อนและอากาศจะถูกปล่อยออกจากด้านบนของหอทำความเย็นและออกจากบริเวณฟิล ด้วยวิธีนี้ หอทำความเย็นจะระบายความร้อนให้กับน้ำอุ่นอย่างต่อเนื่องโดยการเอาอากาศอุ่นออกจากด้านบนและทำให้อากาศเย็นลงจากด้านล่าง

น้ำเย็นมักจะขจัดความร้อนทิ้งจากการผลิตทางอุตสาหกรรมหรือกระบวนการทำความเย็น หอคอยเป็นตัวแลกเปลี่ยนความร้อนระหว่างอากาศภายในหอคอยและน้ำหล่อเย็นที่ลำเลียงความร้อนทิ้ง

ฉันควรเลือกวัสดุเติมคูลลิ่งทาวเวอร์แบบใด

ในหอทำความเย็น ฟิลแบบสแปลชและฟิล์มฟิลฟจะทำงานร่วมกันได้ดีเพื่อเร่งการระเหยและการทำความเย็น ในทางกลับกัน ฟิล์มฟิลจะสร้างพื้นที่ผิวที่กว้างขวางยิ่งขึ้นและประสิทธิภาพที่เหมาะสมที่สุด ทำให้การส่งผ่านความร้อนมีประสิทธิภาพมากขึ้น อย่างไรก็ตาม มีแนวโน้มที่จะสึกหรอได้ง่ายกว่าเนื่องจากจะต้องจุ่มอยู่ในน้ำที่อุณหภูมิสูงมากตลอดเวลา

เพื่อประสิทธิภาพสูงสุด ให้พิจารณาใช้สแปลชฟิลในการใช้งานหอทำความเย็นซึ่งจำเป็นต้องมีน้ำหมุนเวียนที่มีปริมาณของแข็งสูงและคุณภาพต่ำ นอกจากนี้ ฟิลแบบสแปลชที่มีแถบโลหะอาจเป็นตัวเลือกที่ดี หากน้ำในระบบมีอุณหภูมิสูงมาก ฟิล์มฟิลจะสลายตัวเร็วกว่า

ในโรงงานผลิตส่วนใหญ่ หอทำความเย็นถือเป็นอุปกรณ์ที่จำเป็น ด้วยข้อมูลนี้ คุณสามารถเลือกประเภทวัสดุฟิลหอทำความเย็นที่เหมาะสมที่สุด เพื่อให้แน่ใจว่าหอทำความเย็นในธุรกิจของคุณดำเนินไปอย่างมีประสิทธิภาพสูงสุด

หอทำความเย็นเป็นส่วนประกอบหลักในการลดความร้อนของน้ำในการดำเนินอุตสาหกรรม

เมื่อใช้หอทำความเย็นในการผลิตภาคอุตสาหกรรม มีความเสี่ยงที่จะมีอุณหภูมิของน้ำสูงเกินไป การกระจายความร้อนที่ไม่มีประสิทธิภาพ และการหยุดนิ่งของการผลิต องค์ประกอบหลักที่ส่งเสริมวัฏจักรความร้อนใต้พิภพคือการบรรจุหอทำความเย็น ส่งผลให้เราต้องใช้บรรจุภัณฑ์หอทำความเย็นที่มีความสามารถสูงสุด

ประการแรก ขนาดปกติของหอทำความเย็นแบบไขว้กระแสลม

หนึ่งเท่าครึ่งของเส้นผ่านศูนย์กลางของพัดลมควรแยกส่วนบนของหอทำความเย็นออกจากด้านล่างของพัดลม

ประการที่สอง มุมมาตรฐานของหอทำความเย็นทวนกระแสลม

1.ควรปรับด้านบนบรรจุและส่วนการไหลของอากาศของหอทำความเย็นทวนกระแสลมให้อยู่ภายในเก้าสิบองศา มีการวางคอยล์เปลี่ยนทิศทาง และใช้ฝาครอบด้านบนแบบเรียบ ส่วนการไหลของอากาศและเครื่องกำจัดน้ำมีมุมระหว่าง 90 ถึง 120 องศา

2.ด้านบนของหอแบบหด: ควรควบคุม 90 ถึง 110 องศาที่มุมด้านบนของฝาครอบส่วนการหดตัว

3.มีช่วงการควบคุม 5-8 องศาสำหรับมุมเติมน้ำ

4.ควรเปิดใช้งานกลไกการหมุนเวียนสำรองระหว่างการทำงานเพื่อหลีกเลี่ยงการลัดวงจรระหว่างอากาศและด้านล่างของบรรจุภัณฑ์

ในสภาพอากาศหนาวเย็น เราต้องใช้วัสดุฟิลเลอร์ประเภทอื่น เราควรเลือกอันที่มีความทนทานต่อความเย็นสูงตามอุณหภูมิในท้องถิ่น ความร้อนและความต้านทานของบรรจุภัณฑ์หอทำความเย็นควรถูกกำหนดโดยการตรวจสอบพัดลมอย่างละเอียด พิจารณาการบรรจุหอทำความเย็นที่ดีที่สุดโดยใช้การคำนวณ

คำสุดท้าย: ความสำคัญของฟิลหอทำความเย็น ไอซีเอส

สำหรับองค์กรการผลิตส่วนใหญ่ หอทำความเย็นถือเป็นสิ่งสำคัญ การมีความรู้เพียงพอเกี่ยวกับหอทำความเย็นและชิ้นส่วนต่างๆ สามารถช่วยให้คุณเลือกฟิลของหอทำความเย็นที่ดีที่สุดเพื่อให้อุปกรณ์ของคุณมีประสิทธิภาพดีที่สุดและเพิ่มประสิทธิภาพได้ เลือกวัสดุอุดเฉพาะสำหรับสภาพอากาศหนาวเย็นตามอุณหภูมิในท้องถิ่น ก็ควรใช้ฟิลเลอร์ที่มีความต้านทานต่อความเย็นสูง

ซัพพลายเออร์ชั้นนำของฟิลหอทำความเย็นคือ Industrial Cooling Solutions กรุณาติดต่อเราทันทีหากคุณสนใจผลิตภัณฑ์ฟิลหอทำความเย็นของเรา!