หอทำความเย็นมีบทบาทสำคัญในการรักษาอุณหภูมิที่เหมาะสมสำหรับกระบวนการทางอุตสาหกรรมต่างๆ รวมถึงระบบการผลิตไฟฟ้า ปิโตรเคมี เคมี กระบวนการ และระบบ HVAC หอทำความเย็นเหล่านี้มีหน้าที่กระจายความร้อนส่วนเกินออกสู่ชั้นบรรยากาศ เช่นเดียวกับระบบกลไกอื่นๆ หอหล่อเย็นต้องการการบำรุงรักษาเป็นประจำเพื่อให้มั่นใจว่าจะมีอายุการใช้งานยาวนานและมีประสิทธิภาพ ที่สำคัญ การละเลยการบำรุงรักษาสามารถนำไปสู่ประสิทธิภาพที่ลดลง การซ่อมแซมที่มีราคาแพง และอันตรายด้านความปลอดภัยที่อาจเกิดขึ้น โพสต์ในบล็อกนี้มีรายการตรวจสอบการบำรุงรักษาหอทำความเย็นแบบทีละขั้นตอนที่เรียบง่ายและครอบคลุม ซึ่งจะช่วยให้คุณรักษาหอทำความเย็นของคุณทำงานได้อย่างมีประสิทธิภาพและราบรื่น

รายการตรวจสอบที่เป็นประโยชน์นี้จะช่วยให้คุณได้รับข้อมูลเชิงลึกอันมีค่าในการบำรุงรักษาหอทำความเย็น เพิ่มประสิทธิภาพสูงสุด และยืดอายุการใช้งาน เรามาเจาะลึกและสำรวจขั้นตอนสำคัญเพื่อเก็บรายการตรวจสอบการบำรุงรักษาหอทำความเย็นของคุณเพื่อดูว่าทำงานได้อย่างราบรื่นและมีประสิทธิภาพหรือไม่

คูลลิ่งทาวเวอร์คืออะไร?

หอทำความเย็นเป็นอุปกรณ์เปิดโล่งขนาดใหญ่ที่ออกแบบมาเพื่อทำให้น้ำร้อนหรือของเหลวอื่น ๆ เย็นลงโดยการแยกความร้อนออกสู่ชั้นบรรยากาศ หอหล่อเย็นสามารถบังคับร่าง ร่างเหนี่ยวนำ หรือร่างธรรมชาติ และสามารถพบได้ในโรงงานอุตสาหกรรมและโรงไฟฟ้า โรงกลั่น และแม้แต่อาคารพาณิชย์ขนาดใหญ่

การทำความเข้าใจองค์ประกอบหลัก

หอทำความเย็นประกอบด้วยองค์ประกอบหลักดังต่อไปนี้:

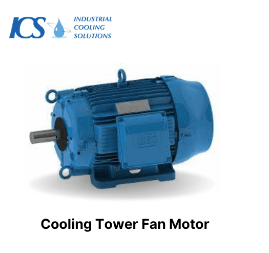

1. ระบบพัดลม ทำหน้าที่สร้างกระแสลมที่จำเป็นสำหรับการกระจายความร้อน

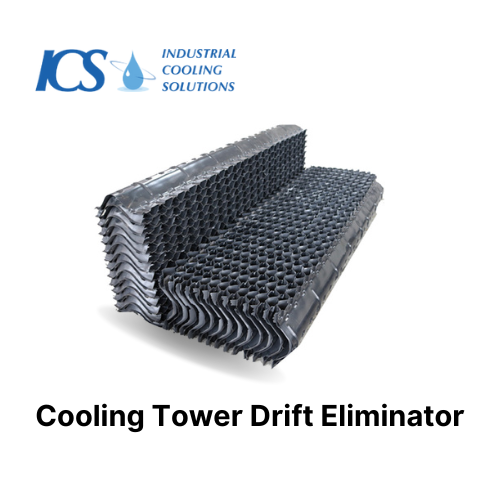

2. เครื่องกำจัดดริฟท์: ส่วนประกอบพิเศษเหล่านี้ป้องกันไม่ให้หยดน้ำถูกพาออกไปโดยอากาศเสีย

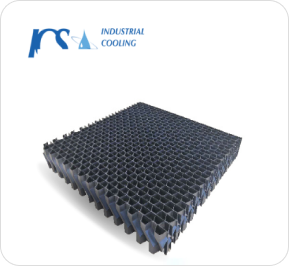

3. วัสดุเติม: ช่วยให้การถ่ายเทความร้อนสะดวกโดยเพิ่มการสัมผัสระหว่างอากาศและน้ำให้สูงสุด ส่งเสริมการระบายความร้อนที่มีประสิทธิภาพ

4. ระบบกระจายน้ำ: กระจายน้ำอย่างสม่ำเสมอทั่วทั้งวัสดุเติมเพื่อให้มั่นใจถึงประสิทธิภาพการทำความเย็นสูงสุด

5. อ่างล้างหน้าและบ่อ: อ่างจะรวบรวมและกักเก็บน้ำเพื่อการหมุนเวียน ในขณะที่บ่อช่วยให้ระบายน้ำได้อย่างเหมาะสม รายการตรวจสอบการบำรุงรักษาหอทำความเย็นแบบทีละขั้นตอน

6. การบำรุงรักษาหอทำความเย็นเป็นประจำมีความสำคัญต่อการทำงานที่มีประสิทธิภาพและอายุการใช้งานที่ยาวนาน นี่คือรายการตรวจสอบทีละขั้นตอนที่สามารถช่วยให้หอทำความเย็นของคุณอยู่ในสภาพที่เหมาะสมที่สุด ดังนั้นตรวจสอบขั้นตอนด้านล่าง

ขั้นตอนที่ 1: ตรวจสอบภายนอกหอคอย

เริ่มต้นด้วยการตรวจสอบภายนอกของหอทำความเย็นด้วยสายตา มองหาสัญญาณของความเสียหายทางกายภาพ การกัดกร่อน หรือการรั่วไหล ตรวจสอบความสมบูรณ์ของโครงสร้าง ใบพัดลม บานเกล็ด และประตูทางเข้า หากคุณพบปัญหาใดๆ ให้จดบันทึกไว้เพื่อตรวจสอบหรือซ่อมแซมเพิ่มเติม น้ำไหลทั่วทั้ง “เขตฝน” หรือไม่? ถ้าไม่เช่นนั้น คุณจะรู้ว่ามีโอกาสที่หัวฉีดหัก เติมอุดตัน หรือปัญหาอื่นๆ ที่น่ากังวล

ขั้นตอนที่ 2: ทำความสะอาดอ่างล้างหน้าและบ่อน้ำ

หอทำความเย็นเป็นเครื่องฟอกอากาศที่มีประสิทธิภาพสูง ดังนั้นอ่างน้ำเย็นและบ่อน้ำของหอทำความเย็นจึงเสี่ยงต่อการสะสมตัวของเศษตะกอน ตะกอน และการเจริญเติบโตของจุลินทรีย์ เริ่มต้นจากการระบายน้ำและทำความสะอาดอ่างล้างหน้าให้สะอาด ขจัดสิ่งสกปรก ใบไม้ หรือวัตถุแปลกปลอมอื่นๆ ที่สะสมอยู่ ใช้ไบโอไซด์หรือสารทำความสะอาดที่เหมาะสมเพื่อกำจัดแบคทีเรีย สาหร่าย และเชื้อราที่อาจทำให้เกิดการเปรอะเปื้อนและลดประสิทธิภาพ

ขั้นตอนที่ 3: ตรวจสอบระบบบำบัดน้ำ

การบำบัดน้ำอย่างเหมาะสมถือเป็นสิ่งสำคัญในการป้องกันตะกรัน การกัดกร่อน และการเติบโตทางชีวภาพภายในระบบหอหล่อเย็น ตรวจสอบอุปกรณ์บำบัดน้ำ รวมถึงเครื่องป้อนสารเคมี ตัวกรอง และระบบควบคุม pH ตรวจสอบให้แน่ใจว่าอุปกรณ์ทำงานอย่างถูกต้อง และปรับอัตราการจ่ายสารเคมีตามความจำเป็น

ขั้นตอนที่ 4: ตรวจสอบตัวกำจัดดริฟท์และเติมวัสดุ

ตัวกำจัดการดริฟท์และการเติมวัสดุมีบทบาทสำคัญในการเพิ่มประสิทธิภาพของหอทำความเย็น ตรวจสอบส่วนประกอบเหล่านี้ว่ามีการอุดตัน สิ่งกีดขวาง หรือสัญญาณของการสึกหรอหรือไม่ กำจัดเศษหรือตะกรันออกจากเครื่องกำจัดดริฟท์ และตรวจสอบให้แน่ใจว่าวัสดุเติมอยู่ในสภาพสมบูรณ์และกระจายน้ำอย่างสม่ำเสมอทั่วทั้งเซลล์แต่ละเซลล์

ขั้นตอนที่ 5: ตรวจสอบระบบพัดลม

ระบบพัดลมมีความสำคัญอย่างยิ่งต่อการไหลเวียนของอากาศและการกระจายความร้อนที่เหมาะสม ตรวจสอบใบพัดลมว่ามีความเสียหายหรือความไม่สมดุลหรือไม่ ตรวจสอบว่ามอเตอร์พัดลม ข้อต่อ และกระปุกเกียร์อยู่ในสภาพดีและอยู่ในแนวที่ถูกต้อง หล่อลื่นแบริ่งและเปลี่ยนน้ำมันเกียร์ตามคำแนะนำของผู้ผลิต

ขั้นตอนที่ 6: ตรวจสอบระบบจ่ายน้ำ

ระบบจ่ายน้ำช่วยให้มั่นใจได้ว่าน้ำจะไหลผ่านวัสดุเติม ตรวจสอบหัวฉีดสเปรย์ที่อุดตันหรือชำรุด ปรับหรือเปลี่ยนหัวฉีดที่ชำรุดเพื่อรักษาการกระจายน้ำที่สม่ำเสมอและป้องกันจุดแห้งซึ่งทำให้การระบายความร้อนไม่มีประสิทธิภาพ

ขั้นตอนที่ 7: ทำความสะอาดและตรวจสอบท่อน้ำ

ตรวจสอบระบบท่อน้ำว่ามีรอยรั่ว การกัดกร่อน หรือการอุดตันหรือไม่ กำจัดตะกรันหรือคราบสะสมที่อาจสะสมอยู่ ตรวจสอบวาล์ว ข้อต่อ และข้อต่อเพื่อการทำงานที่เหมาะสมและความแน่นหนา ซ่อมแซมหรือเปลี่ยนส่วนประกอบที่เสียหายตามความจำเป็น

ขั้นตอนที่ 8: ทดสอบคุณภาพน้ำ

การทดสอบคุณภาพน้ำเป็นประจำถือเป็นสิ่งสำคัญในการตรวจสอบพารามิเตอร์ต่างๆ เช่น pH การนำไฟฟ้า และปริมาณของแข็งที่ละลายได้ทั้งหมด (TDS) เก็บตัวอย่างน้ำและดำเนินการทดสอบโดยใช้ชุดทดสอบที่เหมาะสม หรือส่งไปยังห้องปฏิบัติการที่ได้รับการรับรอง นอกจากนี้ ให้ปรับพารามิเตอร์การบำบัดน้ำตามผลลัพธ์เพื่อรักษาสภาวะที่เหมาะสมที่สุด

ขั้นตอนที่ 9: จัดทำเอกสารและกำหนดเวลางานบำรุงรักษา

เก็บบันทึกโดยละเอียดของกิจกรรมการบำรุงรักษาทั้งหมด รวมถึงการตรวจสอบ การซ่อมแซม และการปรับการบำบัดน้ำ สร้างกำหนดการบำรุงรักษาตามคำแนะนำของผู้ผลิตและการสังเกตของคุณ ดังนั้นควรตรวจสอบและอัปเดตกำหนดการอย่างสม่ำเสมอเพื่อให้แน่ใจว่าการบำรุงรักษาทันเวลาและเชิงรุก

รายการตรวจสอบการบำรุงรักษาคูลลิ่งทาวเวอร์ที่ครอบคลุม: ตั้งแต่การตรวจสอบรายวันไปจนถึงการตรวจสอบประจำปี

รายวัน

• ตรวจสอบรอยรั่ว เสียงที่ผิดปกติ หรือการสั่นสะเทือนที่มองเห็นได้

• ตรวจสอบระดับน้ำและให้แน่ใจว่าอยู่ภายในช่วงที่แนะนำ

• ตรวจสอบอุณหภูมิของน้ำและมาตรวัดความดัน

• ตรวจสอบการทำงานของพัดลมและให้แน่ใจว่าการทำงานถูกต้อง

• เดินรอบขอบหอคอยเพื่อตรวจสอบความสมดุลในเขตฝน

รายไตรมาส

• ดำเนินการตรวจสอบภายนอกของหอคอยอย่างละเอียด รวมถึงความสมบูรณ์ของโครงสร้าง ใบพัดลม และบานเกล็ด

• ตรวจสอบและทำความสะอาดเครื่องกรองน้ำหรือตัวกรอง

• ตรวจสอบและหล่อลื่นแบริ่งมอเตอร์พัดลมและระดับน้ำมันเกียร์และสภาพ..

• ทดสอบพารามิเตอร์คุณภาพน้ำ เช่น pH การนำไฟฟ้า และ TDS

กึ่งปี

• ดำเนินการตรวจสอบระบบจ่ายน้ำอย่างครอบคลุม รวมถึงท่อ วาล์ว และข้อต่อต่างๆ

• ตรวจสอบวัสดุอุดว่ามีร่องรอยของความเสียหายหรือคราบสกปรกหรือไม่

• ตรวจสอบข้อต่อการจัดตำแหน่งในระบบพัดลม

• ทำความสะอาดหรือเปลี่ยนหัวฉีดสเปรย์ที่อุดตันหรือชำรุด

เป็นประจำทุกปี

• ดำเนินการตรวจสอบระบบคูลลิ่งทาวเวอร์โดยละเอียด รวมถึงส่วนประกอบทางกลและไฟฟ้า

• ตรวจสอบใบพัดลมเพื่อดูรอยแตก ความสมดุล และการวางแนว

• ชั่งน้ำหนักบล็อกเติมที่เลือกจากระดับที่ต่ำกว่า และบันทึกน้ำหนักเพื่อวัดการเปรอะเปื้อน

• ตรวจสอบและทำความสะอาดแอ่งน้ำและบ่อน้ำ

• ตรวจสอบและปรับระบบบำบัดน้ำ รวมถึงเครื่องป้อนสารเคมีและอุปกรณ์ควบคุม

• ดำเนินการทำความสะอาดและตรวจสอบท่อน้ำและอุปกรณ์ที่เกี่ยวข้องอย่างละเอียดถี่ถ้วน

การเตรียมคูลลิ่งทาวเวอร์ในช่วงที่ไม่ได้ใช้งาน

ก่อนที่จะปิดคูลลิ่งทาวเวอร์เป็นเวลานาน จำเป็นต้องปฏิบัติตามขั้นตอนต่อไปนี้:

ทำความสะอาดอย่างละเอียด

ทำความสะอาดระบบหอหล่อเย็นทั้งหมด รวมถึงอ่างล้างหน้า บ่อ วัสดุเติม และระบบจ่ายน้ำ กำจัดเศษ ตะกอน หรือการเจริญเติบโตทางชีวภาพที่อาจสะสมอยู่ ซึ่งจะช่วยป้องกันการกัดกร่อน การเปรอะเปื้อน และการแพร่กระจายของจุลินทรีย์ที่เป็นอันตราย

ระบายระบบ

ระบายระบบคูลลิ่งทาวเวอร์ให้หมดเพื่อกำจัดน้ำทั้งหมด ซึ่งจะช่วยลดความเสี่ยงของน้ำนิ่ง ซึ่งอาจนำไปสู่การเจริญเติบโตของแบคทีเรีย การเกิดตะกรัน และการกัดกร่อน ตรวจสอบให้แน่ใจว่าระบบแห้งและไม่มีความชื้นก่อนดำเนินการต่อ

ตรวจสอบและซ่อมแซม

ดำเนินการตรวจสอบส่วนประกอบหอทำความเย็นอย่างครอบคลุม มองหาสัญญาณของความเสียหาย เช่น รอยแตก รอยรั่ว หรือชิ้นส่วนที่ชำรุด จัดการและแก้ไขปัญหาเหล่านี้ก่อนที่จะถึงช่วงว่างเพื่อป้องกันการเสื่อมสภาพเพิ่มเติม

ความสำคัญของการบำรุงรักษาเชิงป้องกัน

เช่นเดียวกับระบบกลไกอื่นๆ หอหล่อเย็นจำเป็นต้องได้รับการบำรุงรักษาเป็นประจำเพื่อให้มั่นใจถึงประสิทธิภาพและอายุการใช้งานที่ยาวนาน ต่อไปนี้ เราจะสำรวจว่าเหตุใดการบำรุงรักษาเชิงป้องกันจึงมีความสำคัญสูงสุด

ประสิทธิภาพและสมรรถนะ

การบำรุงรักษาเป็นประจำช่วยให้แน่ใจว่าอาคารยังคงทำงานได้อย่างมีประสิทธิภาพสูงสุด เมื่อเวลาผ่านไป การสะสมของแร่ธาตุ ตะกอน และการเจริญเติบโตทางชีวภาพสามารถสะสมอยู่ภายในหอคอย ซึ่งเป็นอุปสรรคต่อการถ่ายเทความร้อน ซึ่งจะช่วยลดความสามารถในการทำความเย็นและประสิทธิภาพโดยรวมของทาวเวอร์ ด้วยการดำเนินการตรวจสอบ การทำความสะอาด และการบำรุงรักษาเชิงป้องกันเป็นประจำ ปัญหาเหล่านี้จึงสามารถระบุและแก้ไขได้ทันที ช่วยให้หอคอยทำงานได้อย่างเหมาะสมที่สุด

การป้องกันความเสียหายของอุปกรณ์

หอหล่อเย็นเชื่อมโยงกับเครื่องจักรที่มีราคาแพงและมีความสำคัญ การละเลยการบำรุงรักษาอาจนำไปสู่ผลลัพธ์ที่ร้ายแรง เช่น อุปกรณ์ขัดข้อง การหยุดทำงานของโรงงาน และการซ่อมแซมที่มีค่าใช้จ่ายสูง ตัวอย่างเช่น น้ำที่ไม่ผ่านการบำบัดในหอคอยอาจทำให้เกิดการกัดกร่อนและความเปรอะเปื้อนในระบบ นำไปสู่ความเสียหายร้ายแรงต่อระบบโดยรวม การบำรุงรักษาตามปกติ รวมถึงมาตรการบำบัดน้ำและการควบคุมการกัดกร่อน ช่วยปกป้องระบบทำความเย็นทั้งหมด ทำให้มั่นใจได้ถึงอายุการใช้งานที่ยาวนานและการทำงานอย่างต่อเนื่อง

รับรองการปฏิบัติตามกฎระเบียบ

หลายประเทศมีกฎระเบียบและแนวทางปฏิบัติเฉพาะเพื่อให้แน่ใจว่าหอทำความเย็นทำงานอย่างปลอดภัย โดยเฉพาะอย่างยิ่งเกี่ยวกับคุณภาพน้ำและการปล่อยมลพิษ การบำรุงรักษาตามปกติมีบทบาทสำคัญในการปฏิบัติตามมาตรฐานการปฏิบัติตามข้อกำหนดเหล่านี้ ด้วยการดำเนินการตรวจสอบเป็นประจำ ติดตามตรวจสอบเคมีของน้ำ และดำเนินการแก้ไขที่จำเป็น บริษัทต่างๆ สามารถหลีกเลี่ยงบทลงโทษ ปัญหาทางกฎหมาย และผลกระทบด้านลบต่อชื่อเสียงของตนได้

ประสิทธิภาพการใช้พลังงานและการประหยัดต้นทุน

หอคอยที่ได้รับการดูแลอย่างดีใช้พลังงานน้อยลง ส่งผลให้ประหยัดต้นทุนได้อย่างมากสำหรับอุตสาหกรรม หอคอยที่มีการเปรอะเปื้อนหรือบำรุงรักษาไม่ดีต้องใช้พลังงานมากขึ้นเพื่อให้ได้ความเย็นตามที่ต้องการ เพิ่มการใช้พลังงานและค่าสาธารณูปโภค การบำรุงรักษาเป็นประจำ รวมถึงการทำความสะอาดพื้นผิวแลกเปลี่ยนความร้อนและเพิ่มประสิทธิภาพการบำบัดน้ำ ช่วยรักษาการถ่ายเทความร้อนอย่างมีประสิทธิภาพ ลดการใช้พลังงาน และลดต้นทุนการดำเนินงาน

ความห่วงใยด้านสุขภาพและสิ่งแวดล้อม

หอทำความเย็นที่ถูกละเลยสามารถเปลี่ยนเป็นแหล่งเพาะพันธุ์แบคทีเรียที่เป็นอันตรายได้อย่างเหมาะสม รวมถึงลีเจียนเนลลาที่โด่งดัง ซึ่งเป็นอันตรายต่อสุขภาพของมนุษย์ อย่างไรก็ตาม การใช้แนวทางปฏิบัติในการบำรุงรักษาตามปกติ เช่น การฆ่าเชื้อและการตรวจสอบคุณภาพน้ำเป็นประจำ สามารถป้องกันหรือควบคุมการเจริญเติบโตของแบคทีเรียและจุลินทรีย์อื่นๆ ได้อย่างมีประสิทธิภาพ การจัดลำดับความสำคัญของมาตรการบำรุงรักษาเหล่านี้ ไม่เพียงแต่จะรับประกันสภาพแวดล้อมการทำงานที่ปลอดภัยสำหรับพนักงานเท่านั้น แต่ยังป้องกันระบบนิเวศโดยรอบจากการปนเปื้อนที่อาจเกิดขึ้นอีกด้วย

ในสภาพแวดล้อมทางอุตสาหกรรมหรือเชิงพาณิชย์ หอทำความเย็นมีบทบาทสำคัญในการควบคุมอุณหภูมิและรักษาประสิทธิภาพของอุปกรณ์ อย่างไรก็ตาม โครงสร้างเหล่านี้อาจกลายเป็นแหล่งสะสมของแบคทีเรียที่เป็นอันตรายโดยไม่ได้ตั้งใจเมื่อถูกละเลย แบคทีเรียที่น่ากังวลที่สุดคือลีเจียเนลลา ซึ่งอาจทำให้เกิดอาการป่วยทางเดินหายใจอย่างรุนแรงเมื่อสูดดม

เพื่อต่อสู้กับปัญหานี้ การบำรุงรักษาตามปกติเป็นสิ่งสำคัญยิ่ง ด้วยการผสมผสานระเบียบการฆ่าเชื้อโรคตามปกติและการตรวจสอบคุณภาพน้ำอย่างขยันขันแข็ง จึงสามารถจัดการการเติบโตและการแพร่กระจายของแบคทีเรียและจุลินทรีย์อื่นๆ ในเชิงรุกได้ วิธีการป้องกันนี้ช่วยลดความเสี่ยงของการติดเชื้อได้อย่างมาก และปกป้องความเป็นอยู่ที่ดีของพนักงานและใครก็ตามที่สัมผัสกับสภาพแวดล้อมของหอทำความเย็น

ดังนั้นการบำรุงรักษาหอทำความเย็นจึงไม่ใช่แค่งานเสริมเท่านั้น ถือเป็นส่วนสำคัญในการรับรองประสิทธิภาพการดำเนินงาน การปกป้องอุปกรณ์ การปฏิบัติตามกฎระเบียบ และการปกป้องสิ่งแวดล้อม

บทสรุป

การปฏิบัติตามรายการตรวจสอบการบำรุงรักษาหอทำความเย็นแบบทีละขั้นตอนจะช่วยให้คุณรักษาหอทำความเย็นของคุณให้อยู่ในสภาพที่เหมาะสมที่สุด ช่วยให้มั่นใจได้ถึงการกระจายความร้อนที่มีประสิทธิภาพ และป้องกันการพังทลายที่มีค่าใช้จ่ายสูง การตรวจสอบ การทำความสะอาด และการปรับเปลี่ยนเป็นประจำจะช่วยยืดอายุการใช้งานของหอทำความเย็นของคุณ ประหยัดพลังงาน และรักษาความน่าเชื่อถือของกระบวนการทางอุตสาหกรรมของคุณ ด้วยการทุ่มเทเวลาและแรงกายแรงใจในการบำรุงรักษาหอหล่อเย็นอย่างเหมาะสม คุณจะได้รับผลประโยชน์ระยะยาวในแง่ของประสิทธิภาพ การประหยัดต้นทุน และการดำเนินงานที่ไม่หยุดชะงัก

ความพยายามในการบำรุงรักษาอย่างสม่ำเสมอ โดยไม่คำนึงถึงความถี่ จะช่วยให้คุณยืดอายุการใช้งานของหอทำความเย็นของคุณ เพิ่มประสิทธิภาพการใช้พลังงาน ป้องกันความเสียหาย และรับประกันการกระจายความร้อนอย่างมีประสิทธิภาพ ลงทุนในการบำรุงรักษาหอหล่อเย็นอย่างเหมาะสมเพื่อประโยชน์ในการประหยัดต้นทุน ปรับปรุงประสิทธิภาพของระบบ และการดำเนินงานอย่างต่อเนื่อง

รักษาคูลลิ่งทาวเวอร์ของคุณให้ดีที่สุด: ร่วมมือกับผู้เชี่ยวชาญด้าน ICS วันนี้

การบำรุงรักษาหอทำความเย็นเป็นสิ่งสำคัญสำหรับประสิทธิภาพสูงสุด และผู้เชี่ยวชาญที่ ICS พร้อมให้ความช่วยเหลือ ผู้เชี่ยวชาญที่มีทักษะของเรามีความพร้อมที่จะจัดการทุกด้านของการบำรุงรักษาหอทำความเย็น เราพร้อมช่วยเหลือคุณตั้งแต่การตรวจสอบตามปกติไปจนถึงการทำความสะอาดอย่างละเอียดและการซ่อมแซมที่จำเป็น

วางใจให้เราดูแลหอทำความเย็นของคุณทำงานอย่างมีประสิทธิภาพ เพื่อให้มั่นใจถึงสภาพแวดล้อมที่สะดวกสบายและปลอดภัย ติดต่อ ICS วันนี้และให้ทีมผู้เชี่ยวชาญของเราช่วยคุณในการรักษาประสิทธิภาพสูงสุดของหอทำความเย็นของคุณ

คำถามที่พบบ่อยเกี่ยวกับการบำรุงรักษาคูลลิ่งทาวเวอร์

ควรทำการบำรุงรักษาคูลลิ่งทาวเวอร์บ่อยแค่ไหน?

ความถี่ในการบำรุงรักษาหอทำความเย็นขึ้นอยู่กับหลายปัจจัย รวมถึงประเภทของหอทำความเย็น อายุ ความเข้มข้นในการใช้งาน และสภาพแวดล้อม โดยทั่วไป หอหล่อเย็นควรได้รับการบำรุงรักษาตามปกติอย่างน้อยปีละสองครั้ง อย่างไรก็ตาม ในสถานที่ที่มีสภาพอากาศรุนแรงขึ้นหรือมีระดับการปนเปื้อนสูงขึ้น อาจจำเป็นต้องมีการบำรุงรักษาบ่อยขึ้น การตรวจสอบและติดตามอย่างสม่ำเสมอจะกำหนดกำหนดการบำรุงรักษาเฉพาะที่จำเป็นสำหรับหอทำความเย็นแต่ละหอ

งานทั่วไปที่รวมอยู่ในรายการตรวจสอบการบำรุงรักษาหอทำความเย็นมีอะไรบ้าง

รายการตรวจสอบการบำรุงรักษาหอหล่อเย็นโดยทั่วไปประกอบด้วยงานต่างๆ เช่น การทำความสะอาดและการฆ่าเชื้อส่วนเติมของหอ เครื่องกำจัดดริฟท์ และอ่าง การตรวจสอบและการหล่อลื่นส่วนประกอบทางกล เช่น พัดลม มอเตอร์ และกระปุกเกียร์ การทดสอบและการปรับพารามิเตอร์ทางเคมีของน้ำ และตรวจสอบองค์ประกอบโครงสร้างเพื่อหาสัญญาณการกัดกร่อนหรือความเสียหาย นอกจากนี้ยังอาจเกี่ยวข้องกับการตรวจสอบข้อมูลการปฏิบัติงาน การตรวจสอบการตั้งค่าการควบคุม และการดำเนินการประเมินประสิทธิภาพด้านความร้อน