Cooling towers are a need in any industrial setup. Similar parts are found in cooling towers, which cooperate to maintain industrial machinery in good operating order. Throughout the cooling tower’s lifetime, these cooling tower parts will eventually need to be repaired or replaced.

Cooling towers are essential for all industries. The temperature in a factory increases significantly as soon as every piece of machinery and equipment is used. Owners and operators of plants will be more vulnerable to heat-related illnesses and injuries, which could result in equipment failure. The output will probably be lower if industrial machinery is harmed. It is important to take into account the cost of servicing cooling towers and replacing or repairing any damaged elements.

Cooling towers and other industrial equipment are composed of multiple components. When all of these cooling tower parts are working together, they function at their best. The presence of various additional crucial parts, such as a fan, a water pump, and a water supply basin, is another noteworthy characteristic of cooling towers. During the cooling tower’s service life, critical components are frequently repaired or replaced. The essential components of a cooling tower and their functions are as follows:

The names and purposes of the cooling tower parts are included in the details that follow.

Table of Contents (Cooling Tower Parts)

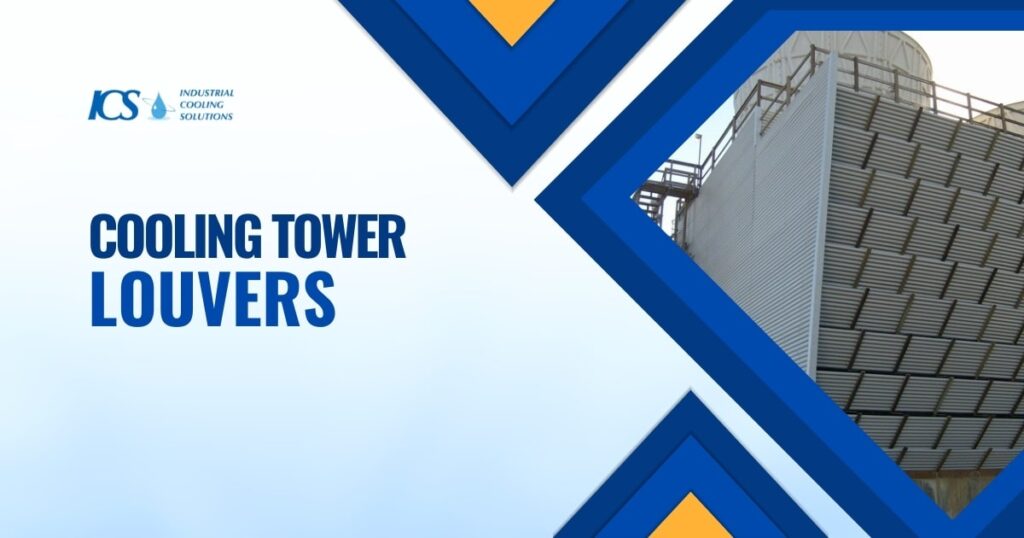

Cooling Tower Louvers

The cooling tower’s air intake louvre acts as a barrier against debris, noise, and water splash-out. They also keep the cooling tower’s inside from being exposed to sunlight.

They could help boost the cooling tower’s airflow while also making the apparatus seem better. The cooling tower would not operate effectively if the louvre was not maintained.

We provide a variety of louvres that are compatible with cooling towers of all brands and types in case you need to replace your louvres. Based on the specifications of your cooling tower, we will fulfil your needs for louvres and ensure their proper installation.

Cooling Tower Fill Media

A crucial component of the cooling tower is the media or fill material. This is also known as the wet surface or deck.

Its primary purpose in cooling towers is to increase the cooling tower’s surface area as quickly as possible to provide the best possible air-water interaction for the greatest amount of time.

Additionally, the fills cause the water to create thin, flowing sheets that may expose a large amount of the contact’s water surface. Increased evaporation rates could result from this.

We offer two different kinds of fill: splash and film fill. They are long-lasting, effective, and UV protected. It’s also simple to install them.

Cooling Tower Fan

fans are used in cooling tower types that include crossflow, mechanical draft, and counterflow. Pressuring air into the cooling tower is these fans’ primary purpose.

The majority of cooling tower fans produce noise. There are, nevertheless, quieter fans available. It is also possible to search for fans that are robust and able to withstand the intricacy of the device’s usage.

Cooling Tower Drift Eliminators

The cooling tower drift eliminator is yet another crucial component of the cooling tower. This component collects the big water droplets from the cooling tower’s air stream. The environment is being impacted by the minerals and chemicals included in the water droplets.

In the meantime, the cooling tower’s drift eliminators prevent water droplets from escaping. The direction of the water droplets is changed, causing them to strike the walls of the blades and then return to the cooling water.

Less than.001% of the recirculating water flow rate is lost due to undesired liquid water leakage thanks to an effective drift eliminator.

Cooling Tower Gear Box

The cooling tower’s large fans and strong motors require cooling tower gearboxes. They perform the function of reducers, lowering the cooling tower fan’s rotational speed from the motor.

In addition to maintaining the motor’s proper size, the cooling tower gears act as a torque multiplier. They also increase the mechanical system’s economic efficiency. The large, heavy cooling tower fan motor could handle the necessary torque required by the fan without the need for these gearboxes. Furthermore, this would be highly costly.

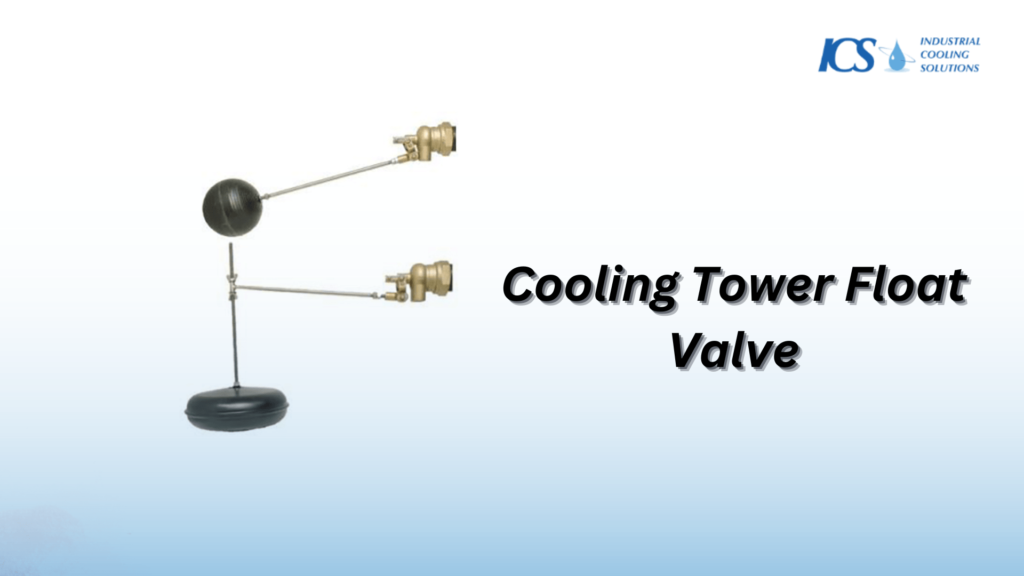

Cooling Tower Float Valve

To keep the water levels inside the cooling tower at the proper levels, float valves are required. They manage and maintain the water level, which may lengthen the cooling tower’s lifespan.

Additionally, these float valves require minimum upkeep. The float arm, the valve, and the float are often included in a full set of float valves.

It takes some trial and error to install the float valve setting correctly so that the makeup water and tower are balanced. Remember that when the pump shuts off, there shouldn’t be any water wasted in the overflow.

Cooling Tower Nozzles

To keep the water levels inside the cooling tower at the proper levels, float valves are required. They manage and maintain the water level, which may lengthen the cooling tower’s lifespan.

Additionally, these float valves require minimum upkeep. The float arm, the valve, and the float are often included in a full set of float valves.

It takes some trial and error to install the float valve setting correctly so that the makeup water and tower are balanced. Remember that when the pump shuts off, there shouldn’t be any water wasted in the overflow.

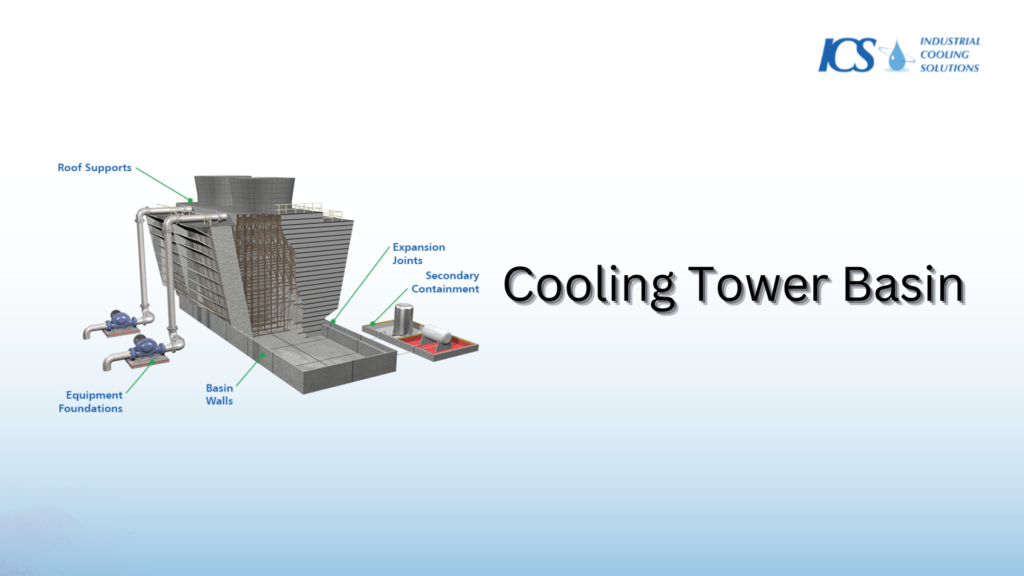

Cooling Tower Basin

There are two types of cooling tower basins: distribution basins and collection basins.

The cooling tower’s bottom, or the collection basin, is where it is situated. Its objective is to gather water and route it towards the pump suction line or sump.

In the meantime, the distribution basin is an elevated, shallow-type basin. Via holes in the basin floor, hot water is distributed to the tower.

Additionally, there is the so-called cold-water basin, which can eliminate standing water and inhibit the growth of bacteria. Because of its easily removable suction strainer, the basin requires minimum maintenance.

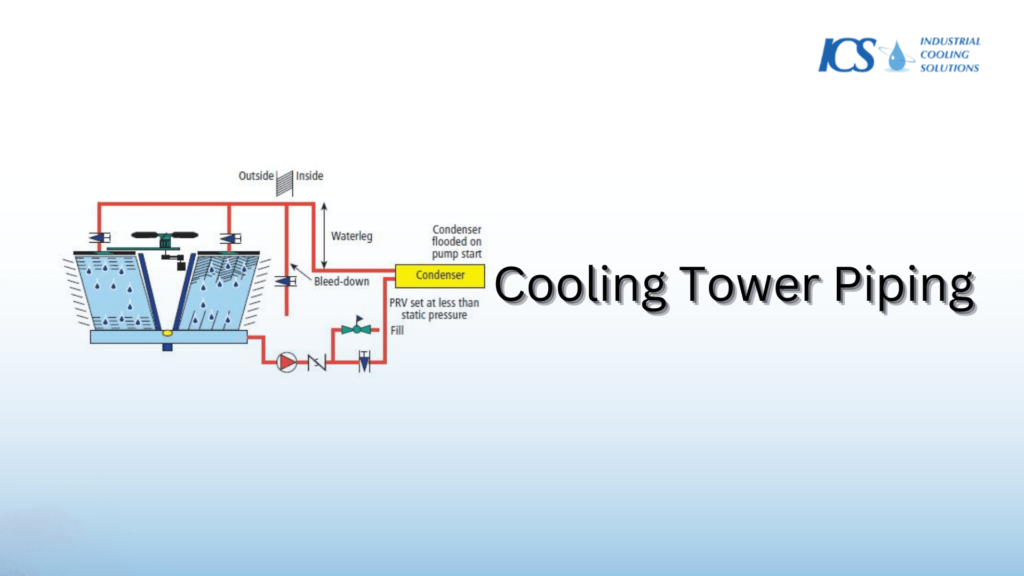

Cooling Tower Piping

Water distribution within the cooling tower is the main purpose of the cooling tower piping. Depending on the type of tower, site design, and topography, the size and layout of the water piping between the heat source and the tower position.

The supply line is normally situated next to the tower’s long side in a supply piping layout.

In the meantime, the supply line to the inlet connection at the tower’s distribution system’s elevation is connected to vertical riser pipes.

Cooling Tower Motor

For cooling tower fans like the mechanical draft cooling tower, the cooling tower motor’s purpose is to power the fans. To survive the harsh environment inside the tower, the motors need to be strong and effective.

Cooling tower motors come in two varieties: completely enclosed and open.

External air is created by the open motor to cool the enclosure. The Fully Enclosed motor, meanwhile, prevents outside air from entering the enclosure.

The Bottom Line

Our cooling tower components are of standard grade and very efficient. They might meet the requirements of your cooling tower and are composed of sturdy materials.

We cordially invite you to review our affordable cooling tower components. You can get in touch with us for more information and help.

We are happy to take care of your needs as soon as possible. We will also go over each cooling tower component’s purpose, installation, and usage in brief.

Replacement cooling tower parts for Marley, BAC, Evapco, Tower Tech, Recold, Imeco, Vilter, and Frigid Coil cooling towers are available from Industrial Cooling Solutions. We provide cooling tower parts of various types and manufactures.