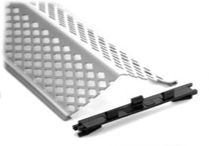

- Patented Mechanical Assembly (MA) technology for glue-free packs that can be assembled on site.

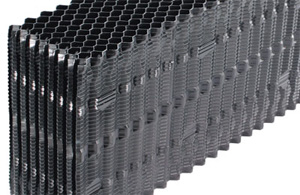

- Modules provide a minimum crush resistance of 500 psf (24 N/m2), which is five times the typical requirement.

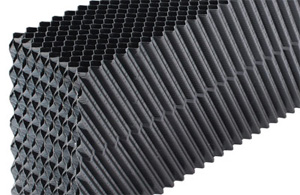

- Advanced geometry allows for over 3,600 drip points per ft3 (127,000/m3).

- Can be used above PVC fills for high temperature applications or improved water distribution.

- Made from a UV-protected polypropylene copolymer.

- Fire-retardant additives available.

- Maximum continuous operation at 176°F (80°C).

- Available in standard 36-inch lengths. Sheets can be lapped to create 72-inch pack lengths.

- Can be cleaned with high-pressure sprayers.